Choosing the right software for your retail business used to be about managing inventory and fulfillment. But today, it’s about managing the work that happens in between. As more brands take on light manufacturing tasks like batching, kitting, or custom assembly, the need for smarter, more flexible tools has never been more urgent.

This guide breaks down what light manufacturing really means in a retail context, what kind of software best supports it, and which platforms stand out across different product categories.

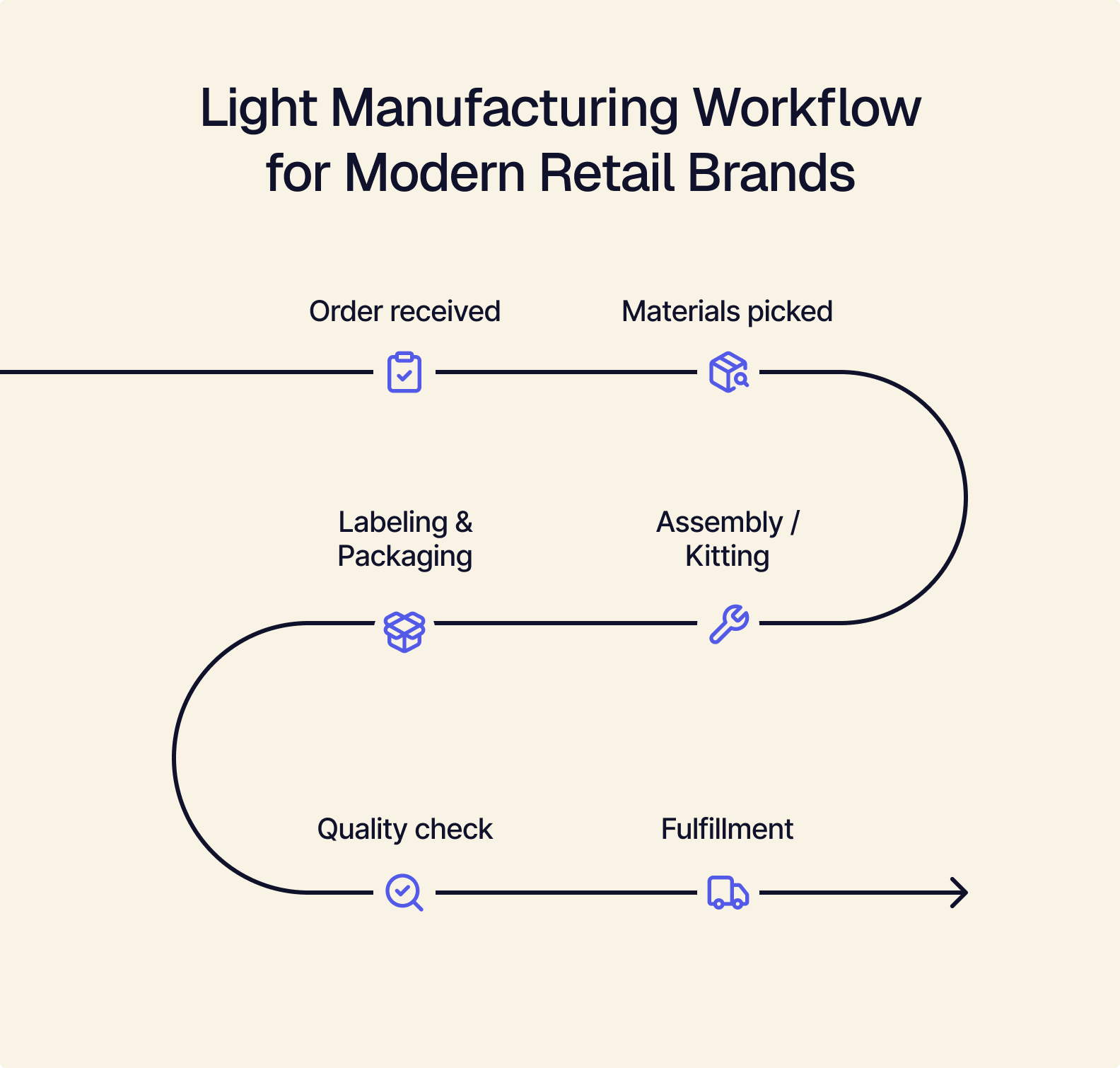

What Is Light Manufacturing in Retail?

Light manufacturing is more than just factory floors, conveyor belts, or robotic arms welding car parts. It’s the everyday, often-overlooked processes that start to resemble production once a retail business reaches a certain level of operational complexity. It’s the skincare brand hand-pouring 500 units of moisturizer for a holiday drop. It’s the apparel startup heat-pressing prints onto tees in a converted garage. It’s the jewelry brand soldering gold settings one at a time while trying to juggle Shopify orders and stockouts. That’s light manufacturing. And it’s everywhere in modern retail, especially in DTC and omnichannel brands growing faster than their back office can keep up.

Unlike full-scale manufacturing, which happens in massive factories and requires advanced MRP systems, light manufacturing is much more tactical and nimble. It usually happens in-house, in partnership with small-batch manufacturers, or via specialized fulfillment teams. These businesses need software that supports agility, not a full-blown industrial platform. That means real-time inventory visibility, intuitive order tracking, fast SKU creation, and flexibility to handle kits, bundles, and made-to-order products without losing their minds.

These workflows don’t feel like manufacturing until one day, they do. Maybe it starts when you can’t track which batch of lip balm used which ingredients. Or when your team builds 10 different bundles and forgets to subtract the raw materials from your inventory. Or when your Shopify integration breaks for the third time this week. That’s the tipping point. And it's where light manufacturing software comes in.

There’s a new generation of tools made for these brands, not for factories, but for fast-moving operations that straddle ecommerce, inventory, fulfillment, and hands-on product creation. These systems digitize your workflows, yes, but they also help you tame them, refine them, and scale them sustainably.

How Light Manufacturing Complexity Factors In

No one builds a factory by accident, but that’s kind of what happens in modern retail. A founder launches a product. It works. Orders pick up. A second product is introduced, then a third. Variations start to stack — different colors, different sizes, different fragrances. Some customers want bundles. Others want gift wrapping. Someone on the team starts managing returns. And just like that, your tech stack is much more complicated than a Shopify ecommerce store. You’re likely using a hodgepodge of tools like Zoho, Odoo, Airtable, Notion, Monday.com, homegrown systems or whatever else you need for your light manufacturing hub.

The signs are subtle at first. Inventory numbers don’t match. Your team spends more time assembling than fulfilling. You’re issuing purchase orders manually and tracking batches in a Google Sheet. You’re struggling to trace which ingredient was used in which order, or which version of the label went to a particular wholesale customer. Eventually, things break.

That’s because the complexity of light manufacturing doesn’t scale linearly — it compounds. One new product with four variations, offered in two bundles, across three channels, equals 24 inventory paths to manage, and that’s before someone requests a custom version. Add wholesale requirements, expiration tracking, and compliance labeling, and it’s no wonder your operations team feels like they’re drowning.

And while this type of work isn’t new, the scale at which small brands are now managing it is. Ten years ago, this was the kind of complexity that required expensive enterprise software and full-time operations managers. Today, even a two-person team running a Shopify store and working with a contract manufacturer can run into these issues.

Retail-native light manufacturing software simplifies what would otherwise require multiple disconnected systems. They track raw materials and finished goods, tie orders to production runs, and help you move from reactive firefighting to proactive planning. Because let’s face it: If you’re spending more time updating spreadsheets than filling orders, your software isn’t working for you. It’s working against you.

What Kind of Software Is Best for Light Manufacturing?

The software you need isn’t something out of the industrial age. It’s not built for factories, forklifts, or Fortune 500 supply chains. What you need is purpose-built, flexible, and ready to handle the weird, wonderful chaos of modern retail operations.

So what does that look like?

- Agility: You should be able to tweak your workflows without a developer or a consultant. Need to add a custom step for packaging, QA, or gift-wrapping? Done.

- End-to-end visibility: Inventory, orders, and production should live under one roof. You shouldn’t need five browser tabs open just to ship a kit.

- API-first architecture: Your software should talk to Shopify, QuickBooks, ShipStation, and whatever else you rely on. No manual re-entry or duplicate records.

- Scalability without rigidity: As your SKU count grows and your workflows evolve, your system should evolve too. You shouldn’t need a reimplementation just to add a new fulfillment rule.

The best light manufacturing systems meet you where you are — and grow alongside you. They’re modular, cloud-native, and built to support retail operations, not replace them.

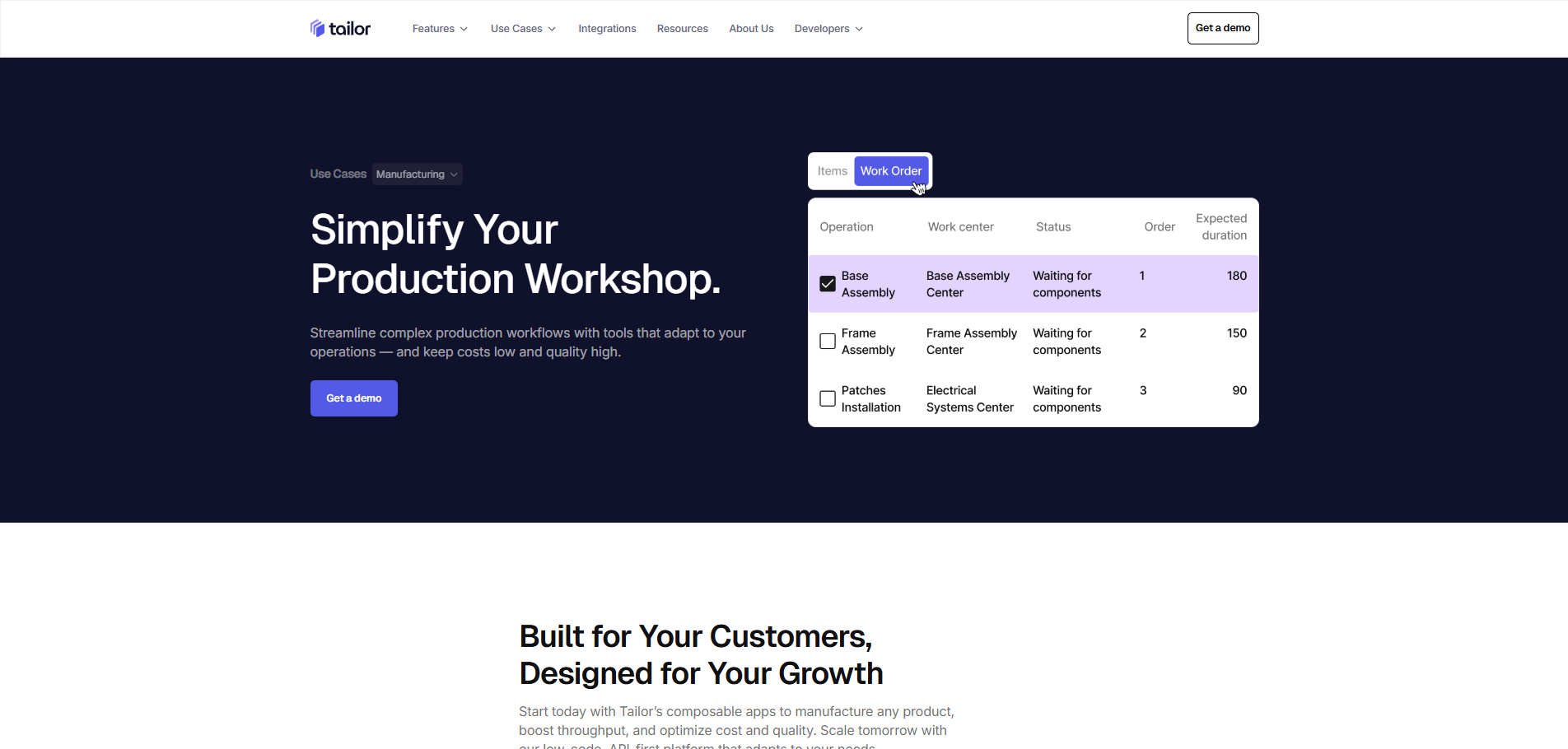

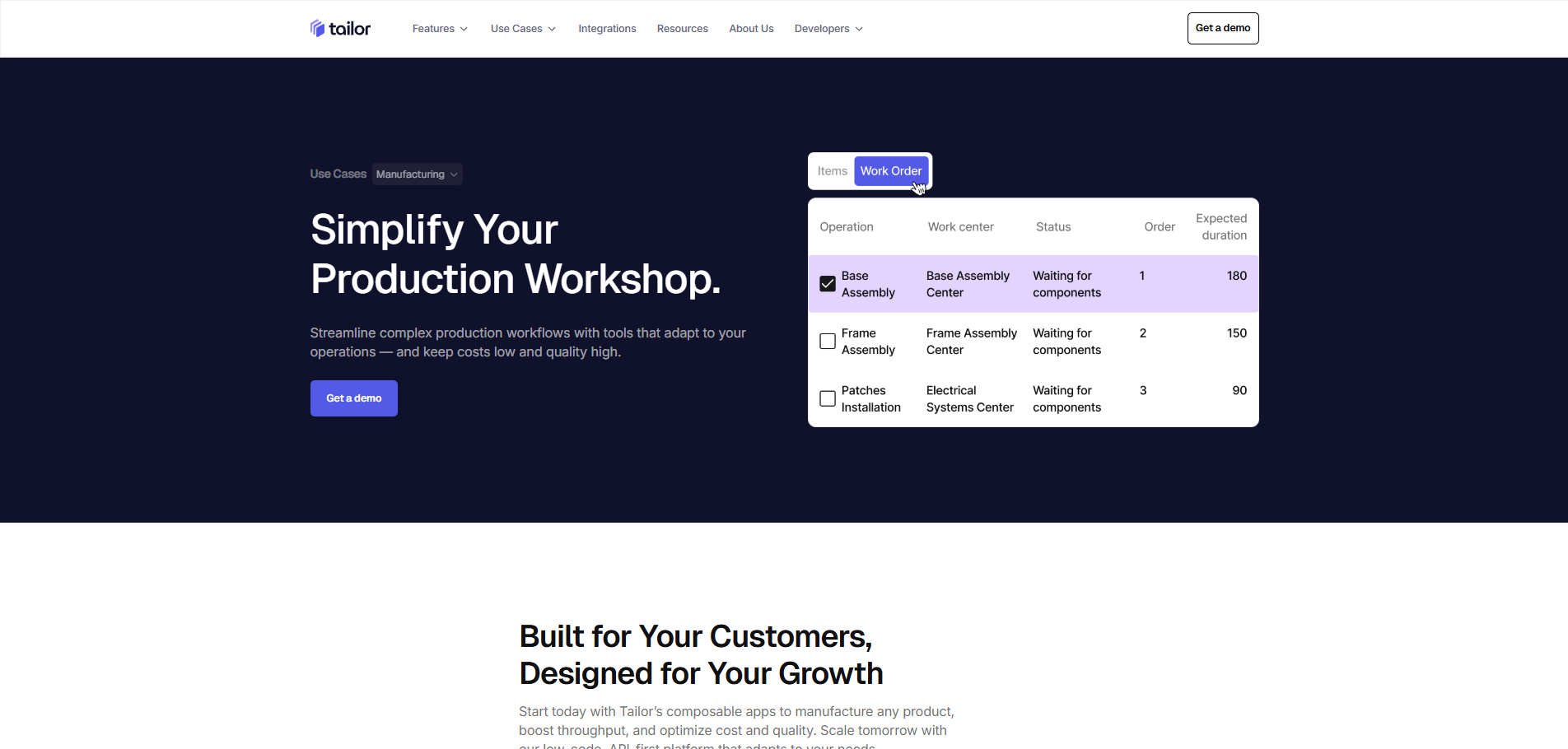

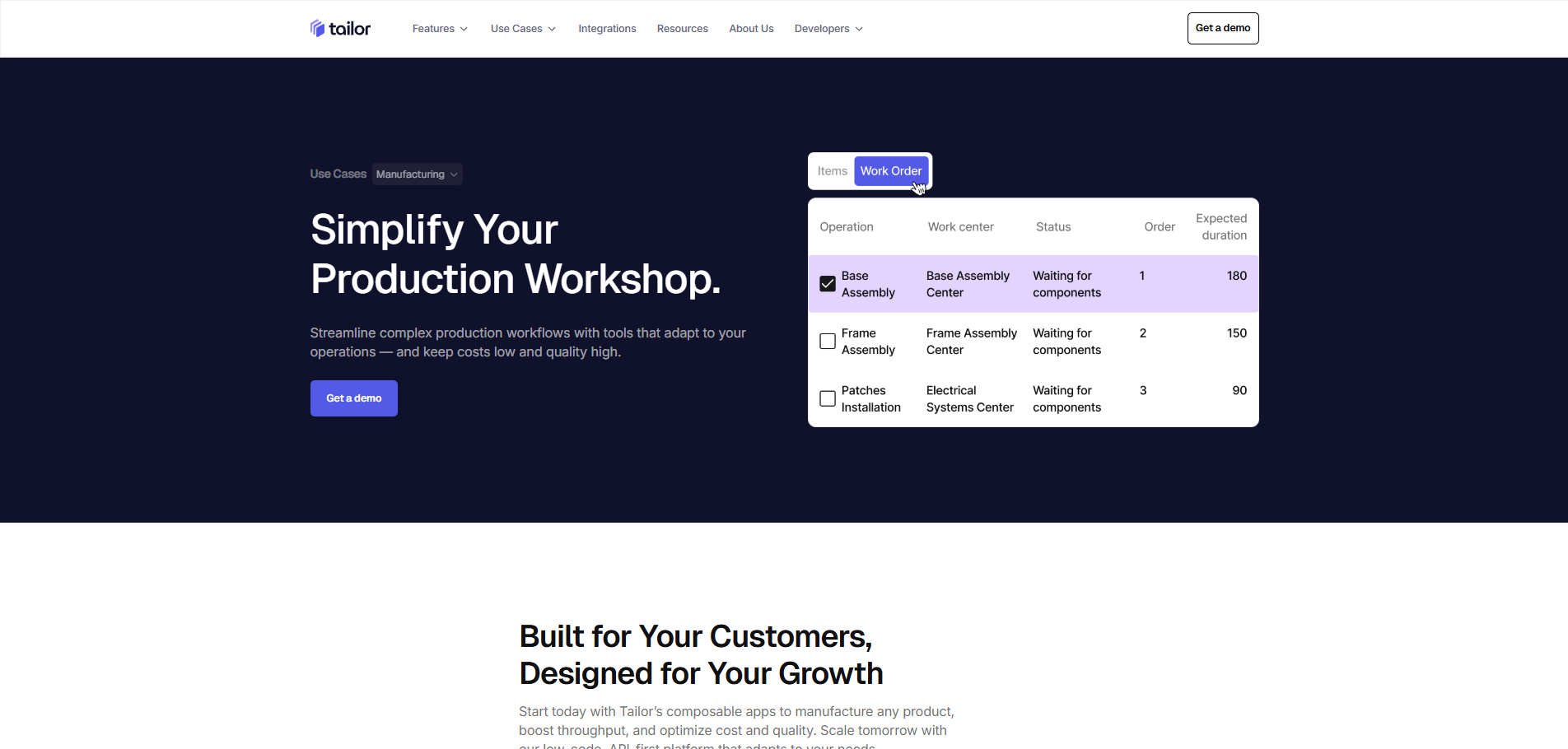

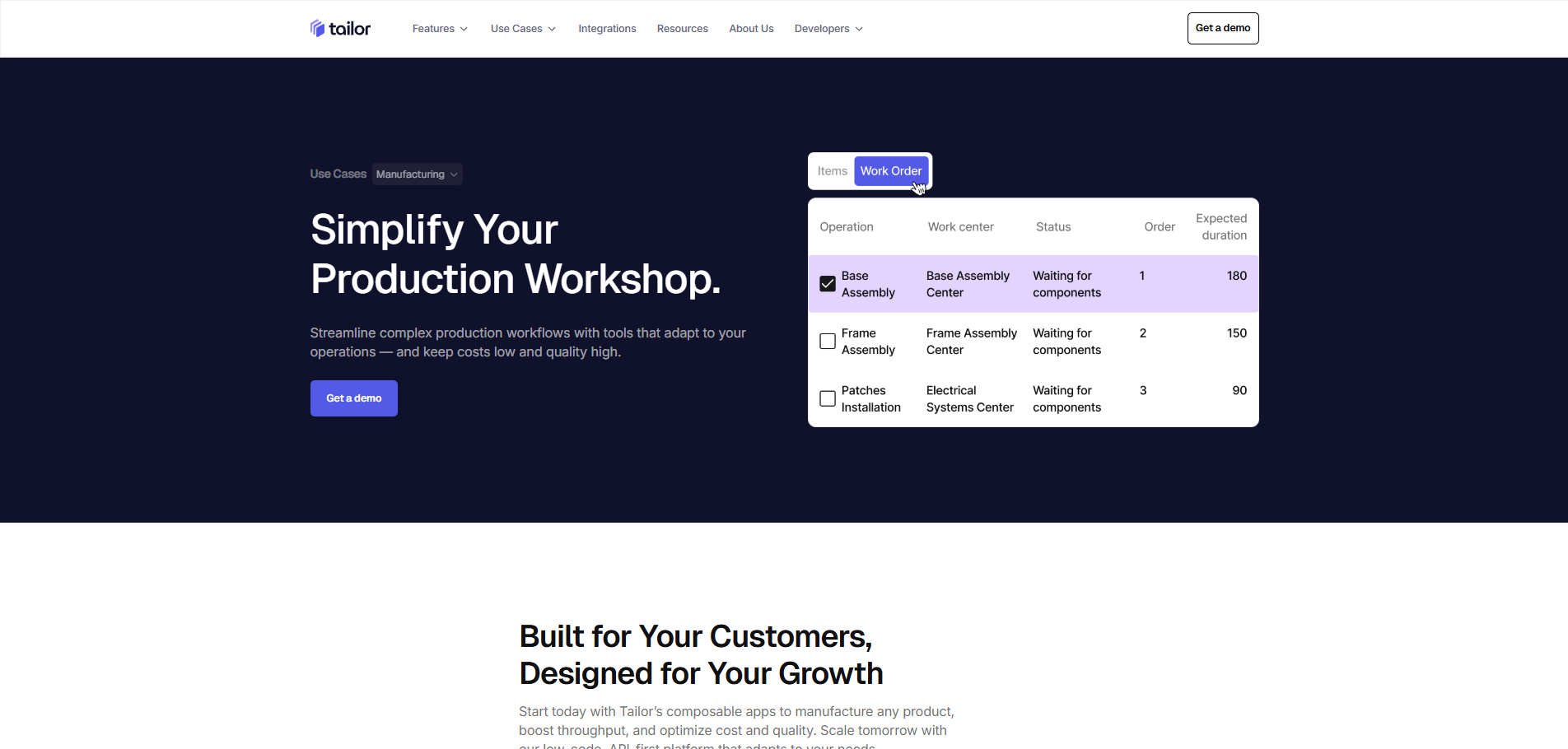

Composable platforms, like Tailor, shine here. Instead of asking you to fit into a rigid system, they provide building blocks you can assemble however you like. Want to track production runs by batch? Create unique labels for each bundle? Sync inventory in real time across DTC and wholesale? These platforms make it happen without disrupting everything else.

When your business needs change every quarter, your software can’t be stuck in place. That’s why composability isn’t a nice-to-have. It’s a survival trait.

Key Features to Look For in Retail Light Manufacturing Software

Ignore the flashy UI and the “AI-powered automation” jargon for a minute. What really matters are the features that make your day-to-day easier, especially when your team is simultaneously juggling raw materials, customer orders, and fulfillment deadlines.

Here’s what to actually look for:

BOM Support (Lite)

You don’t need engineering-level specs, just a clear, flexible way to list what components go into your finished products. Whether it’s a custom bracelet or a skincare kit, the system should automatically deduct raw materials when an item is assembled.

Custom Workflows

Your manufacturing flow probably doesn’t look like anyone else’s. Good software should let you build out a process that matches your products and team, not force you to adopt some rigid, factory-style workflow.

Labeling and Compliance Tools

This is especially important in beauty, food, and health-related verticals. Batch numbers, expiration dates, ingredient listings — your system should help you stay compliant, not create more admin work.

Real-Time Inventory and Material Syncing

This one’s non-negotiable. You need a system that syncs your raw materials and finished goods inventory across locations, channels, and workflows — instantly.

Full Order Visibility

Whether you’re fulfilling DTC orders, wholesale POs, or subscription bundles, your ops team should always know what’s in progress, what’s ready to ship, and what’s blocked.

Plug-and-Play Integrations

It should connect easily with Shopify, QuickBooks, ShipStation, and any other tools in your stack. No Frankenstein builds or double entry.

Throughput Tracking

Even basic throughput metrics (like units completed per shift) can quickly uncover inefficiencies. If the software can show you what’s working and what’s stalling, that’s a win.

Top Light Manufacturing Software Picks by Category

No two retail businesses manufacture exactly the same way. What a skincare startup needs is wildly different from a jewelry maker or a custom apparel brand. That’s why the best software isn’t one-size-fits-all — it’s purpose-built to meet specific industry challenges. Below, we break down the top tools across four key categories, detailing where each one excels and how it supports real retail workflows.

Skincare and Beauty

Skincare and beauty brands operate at the intersection of precision and agility. These companies often deal with perishable ingredients, complex labeling regulations, and small-batch production. Operators of skincare and beauty brands need tools that offer batch tracking, raw material visibility, and compliance-friendly documentation — all while staying nimble enough to support rapid formulation and packaging changes.

Katana is a popular choice for beauty brands looking to bring more visibility and structure to their manufacturing. With visual production scheduling and intuitive inventory control, it’s well-suited to manage raw ingredients, track batches, and ensure consistent output across micro-runs.

Katana is a popular choice for beauty brands looking to bring more visibility and structure to their manufacturing. With visual production scheduling and intuitive inventory control, it’s well-suited to manage raw ingredients, track batches, and ensure consistent output across micro-runs.

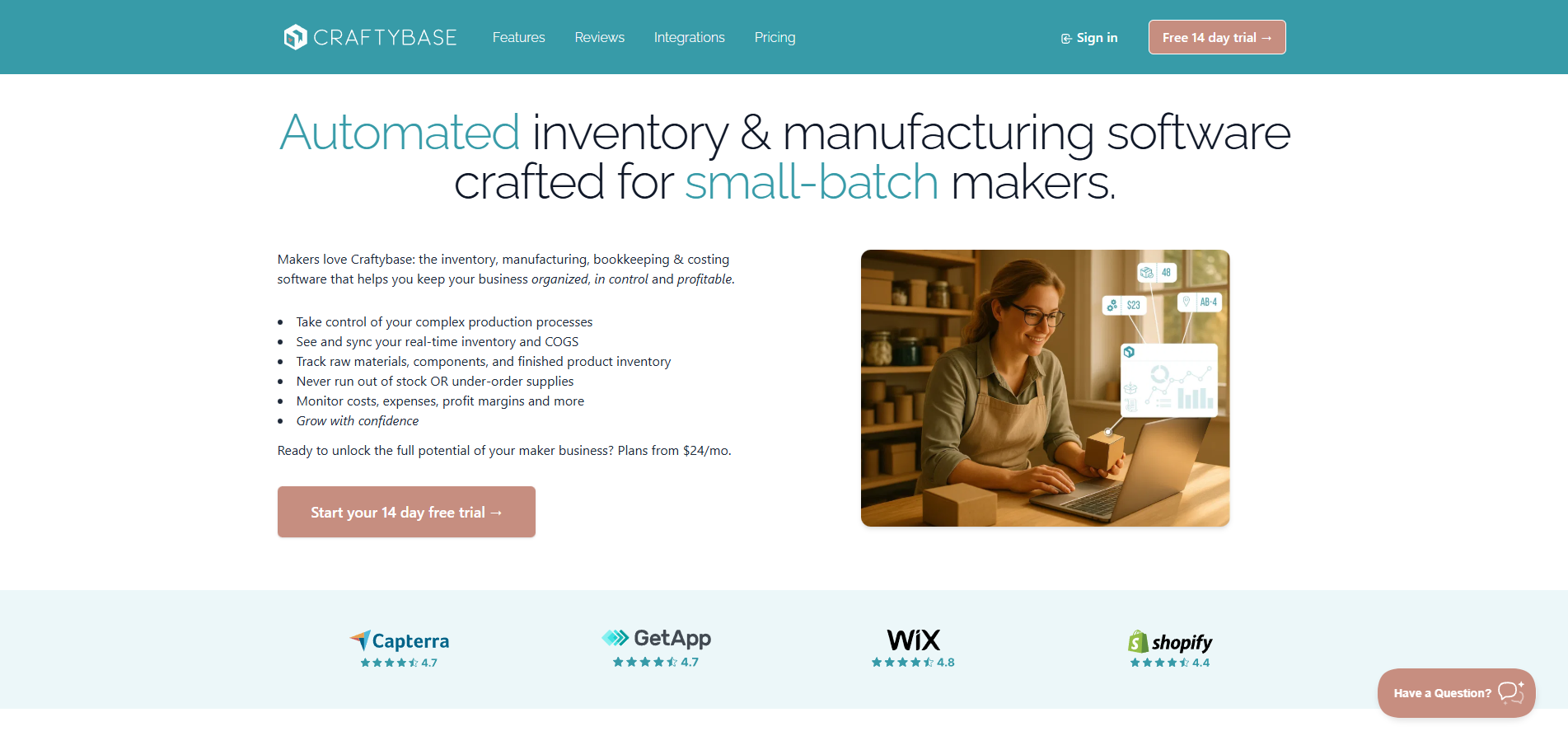

Craftybase is another strong contender, especially for small-batch brands. It combines cost of goods sold (COGS) tracking with compliance reporting, making it easy to manage regulatory labeling, expiration dates, and material usage all in one place. For solo founders or small teams, its maker-focused interface is a huge plus.

Craftybase is another strong contender, especially for small-batch brands. It combines cost of goods sold (COGS) tracking with compliance reporting, making it easy to manage regulatory labeling, expiration dates, and material usage all in one place. For solo founders or small teams, its maker-focused interface is a huge plus.

Finaloop is a relative newcomer but a helpful tool for smaller ecommerce-native brands. It provides read-only API connections that allow you to sync inventory, sales, and accounting for visibility and build pre-defined workflows across supported platforms (like Shopify).

Finaloop is a relative newcomer but a helpful tool for smaller ecommerce-native brands. It provides read-only API connections that allow you to sync inventory, sales, and accounting for visibility and build pre-defined workflows across supported platforms (like Shopify).

Unleashed Software brings more robust manufacturing features into the mix, particularly around ingredient-level traceability and shelf life management. If you’re managing multiple product lines with overlapping materials or navigating strict cosmetic regulations, Unleashed can help you stay ahead of compliance and inventory planning.

Unleashed Software brings more robust manufacturing features into the mix, particularly around ingredient-level traceability and shelf life management. If you’re managing multiple product lines with overlapping materials or navigating strict cosmetic regulations, Unleashed can help you stay ahead of compliance and inventory planning.

Tailor is a headless, composable ERP with flexible inventory management and light manufacturing modules built specifically for fast-growing retail brands. Its composable architecture enables operators to designate the exact compliance and batch-tracking workflows they need. Since Tailor is API-first, it integrates seamlessly with ecommerce platforms, marketplaces, existing scanner hardware and downstream reporting tools for analyzing throughput and assembly efficiency.

Tailor is a headless, composable ERP with flexible inventory management and light manufacturing modules built specifically for fast-growing retail brands. Its composable architecture enables operators to designate the exact compliance and batch-tracking workflows they need. Since Tailor is API-first, it integrates seamlessly with ecommerce platforms, marketplaces, existing scanner hardware and downstream reporting tools for analyzing throughput and assembly efficiency.

Custom Jewelry

Jewelry manufacturing may not involve batch production, but it brings its own complexities: custom orders, one-of-a-kind SKUs, and precise material sourcing. You’re not tracking pallets of goods — you’re tracking grams of gold, counts of stones, and hours of skilled labor.

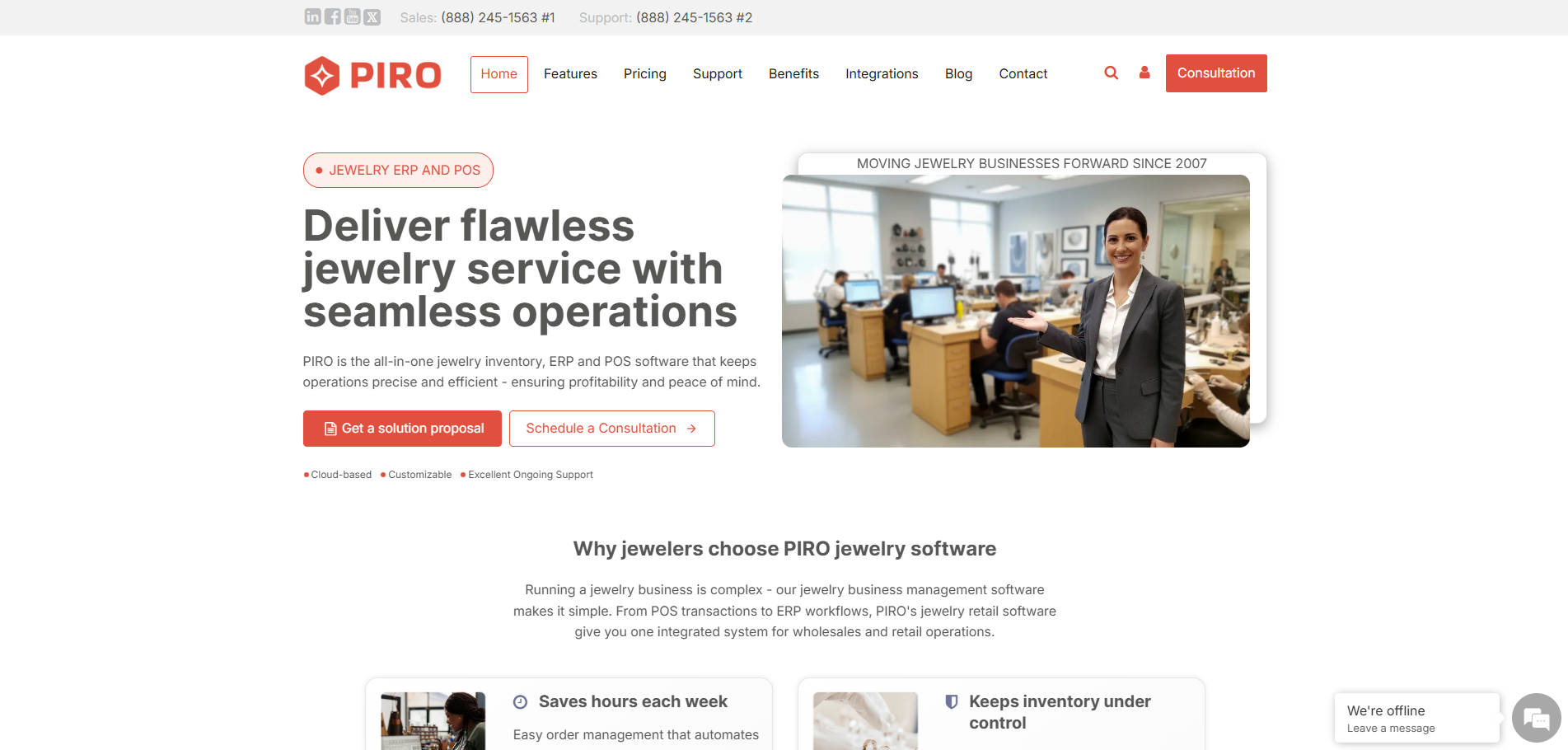

PIRO is purpose-built for jewelry manufacturers and excels where general platforms fall short. It offers detailed material traceability, granular cost-per-piece tracking, and robust job management features that let you track every ring or necklace from raw material to finished product.

PIRO is purpose-built for jewelry manufacturers and excels where general platforms fall short. It offers detailed material traceability, granular cost-per-piece tracking, and robust job management features that let you track every ring or necklace from raw material to finished product.

Katana works surprisingly well here too, especially for brands doing semi-custom or made-to-order pieces. It supports supplier coordination and visual scheduling, which makes managing individual production timelines easier, even when products differ piece by piece.

Katana works surprisingly well here too, especially for brands doing semi-custom or made-to-order pieces. It supports supplier coordination and visual scheduling, which makes managing individual production timelines easier, even when products differ piece by piece.

Craftybase once again proves its versatility. While it doesn’t offer industry-specific features like Jewelry ERP, it handles the essentials beautifully: COGS, inventory deductions, and simplified BOM management for highly unique or custom SKUs.

Craftybase once again proves its versatility. While it doesn’t offer industry-specific features like Jewelry ERP, it handles the essentials beautifully: COGS, inventory deductions, and simplified BOM management for highly unique or custom SKUs.

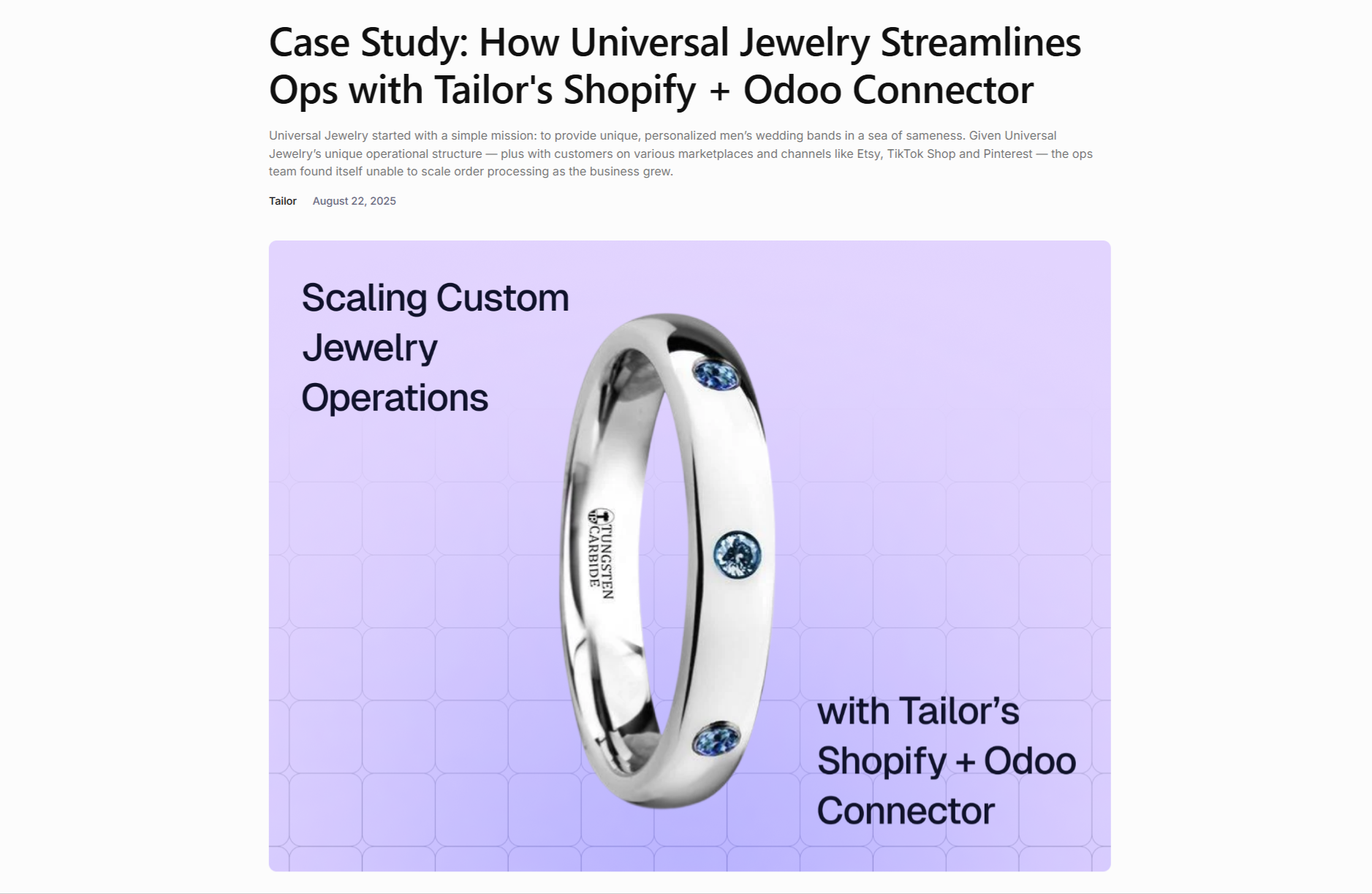

Tailor is a favorite among jewelers for its precision and flexibility. You can build workflows that match your operations, from tracking serialized SKUs by gram or stone to managing multi-step routing (CAD design, casting, setting and finishing). It integrates directly with ecommerce platforms and online marketplaces via API, which syncs ecommerce sales with real-time production (ideal for brands selling custom or made-to-order products on Shopify and other channels like Etsy or Amazon).

Tailor is a favorite among jewelers for its precision and flexibility. You can build workflows that match your operations, from tracking serialized SKUs by gram or stone to managing multi-step routing (CAD design, casting, setting and finishing). It integrates directly with ecommerce platforms and online marketplaces via API, which syncs ecommerce sales with real-time production (ideal for brands selling custom or made-to-order products on Shopify and other channels like Etsy or Amazon).

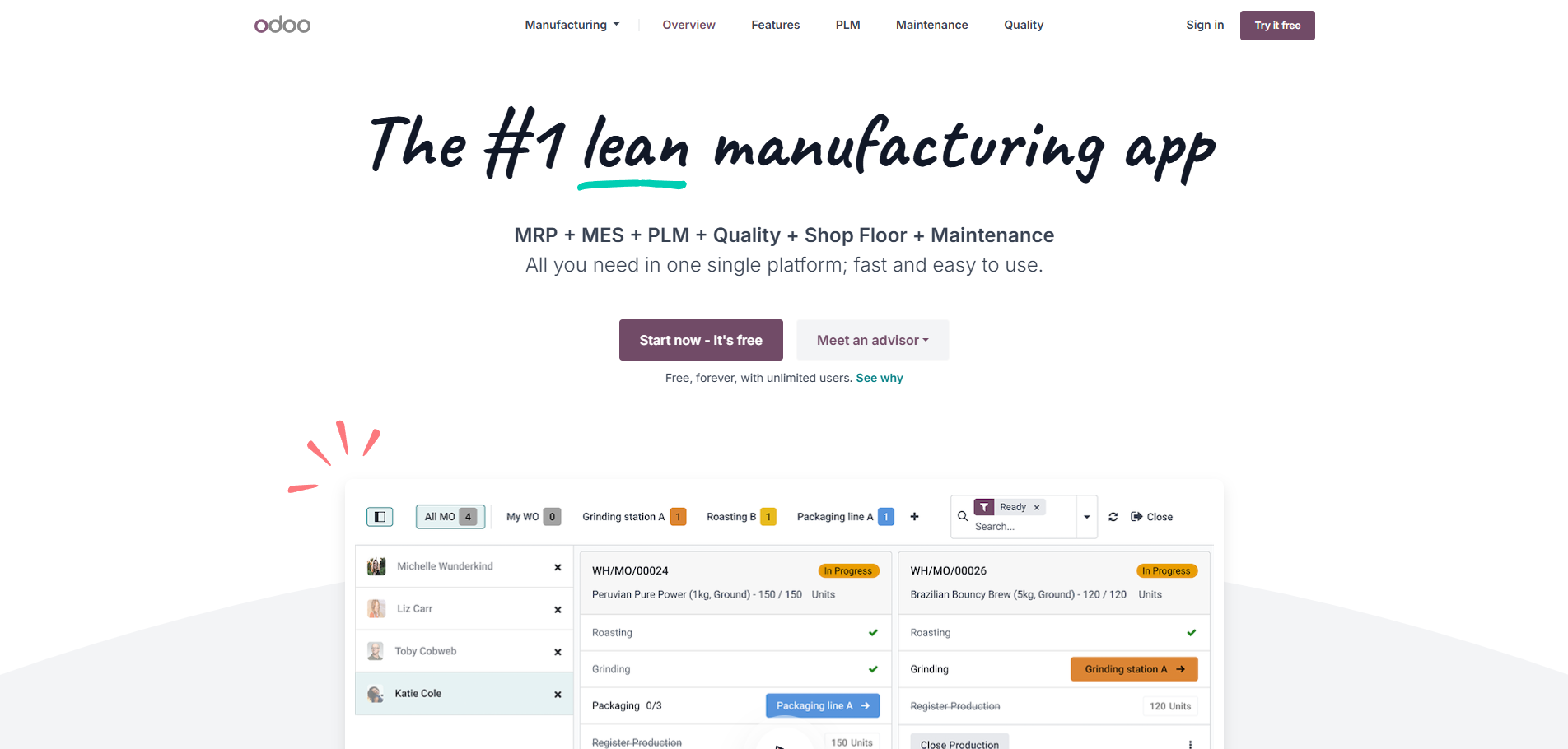

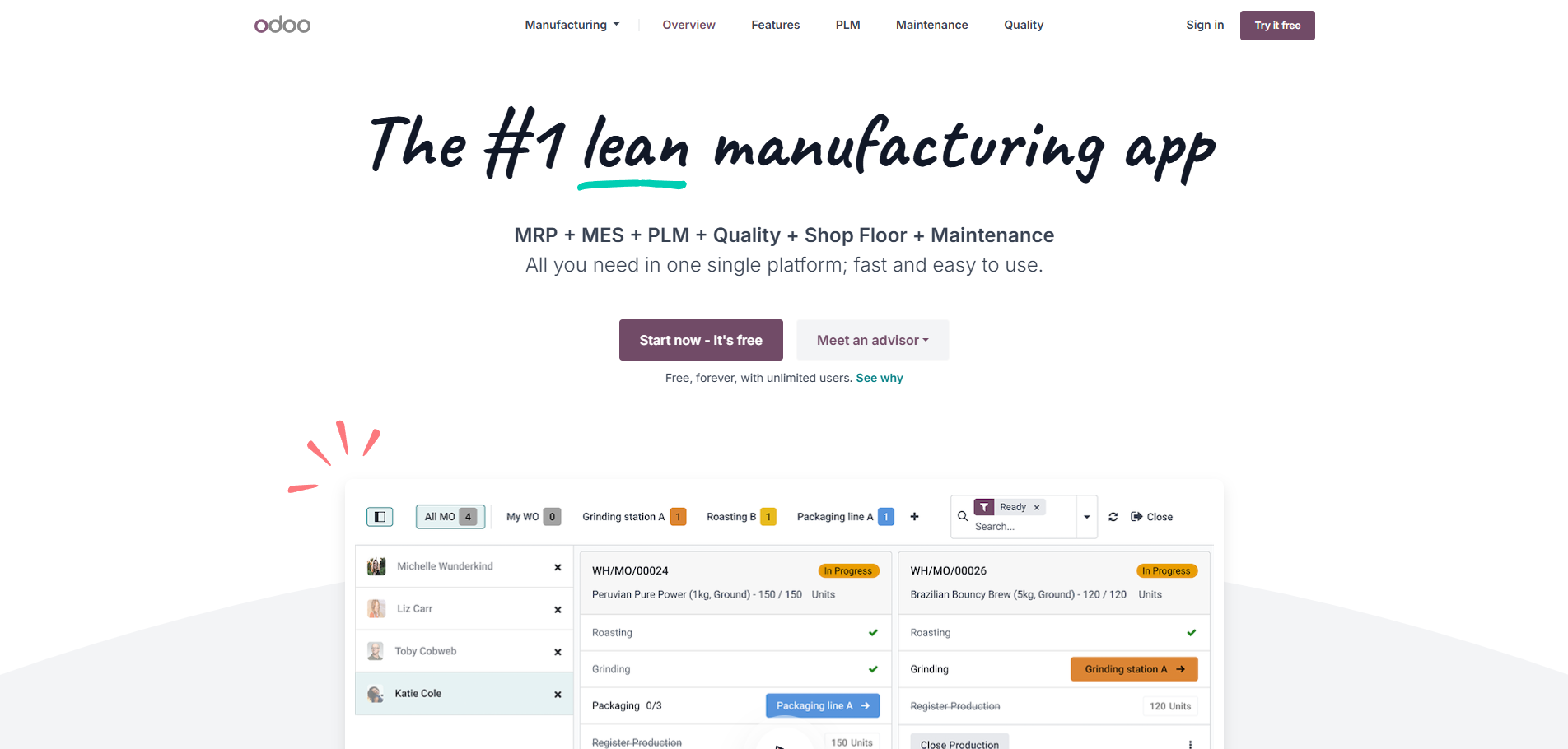

Odoo: While better known as an inventory tool, Odoo can be a viable option for jewelers (with the right in-house or third-party development resources). It supports custom workflows and detailed inventory tracking, but its complexity and setup requirements may be a barrier for smaller teams or quickly scaling brands.

Odoo: While better known as an inventory tool, Odoo can be a viable option for jewelers (with the right in-house or third-party development resources). It supports custom workflows and detailed inventory tracking, but its complexity and setup requirements may be a barrier for smaller teams or quickly scaling brands.

Apparel and Print-on-Demand

The apparel space is a nightmare of variants — color, size, cut, design — compounded by seasonality and fast-moving trends. Add print-on-demand (POD) workflows or returns logistics, and it’s no surprise apparel brands often outgrow their software stack faster than their customer base.

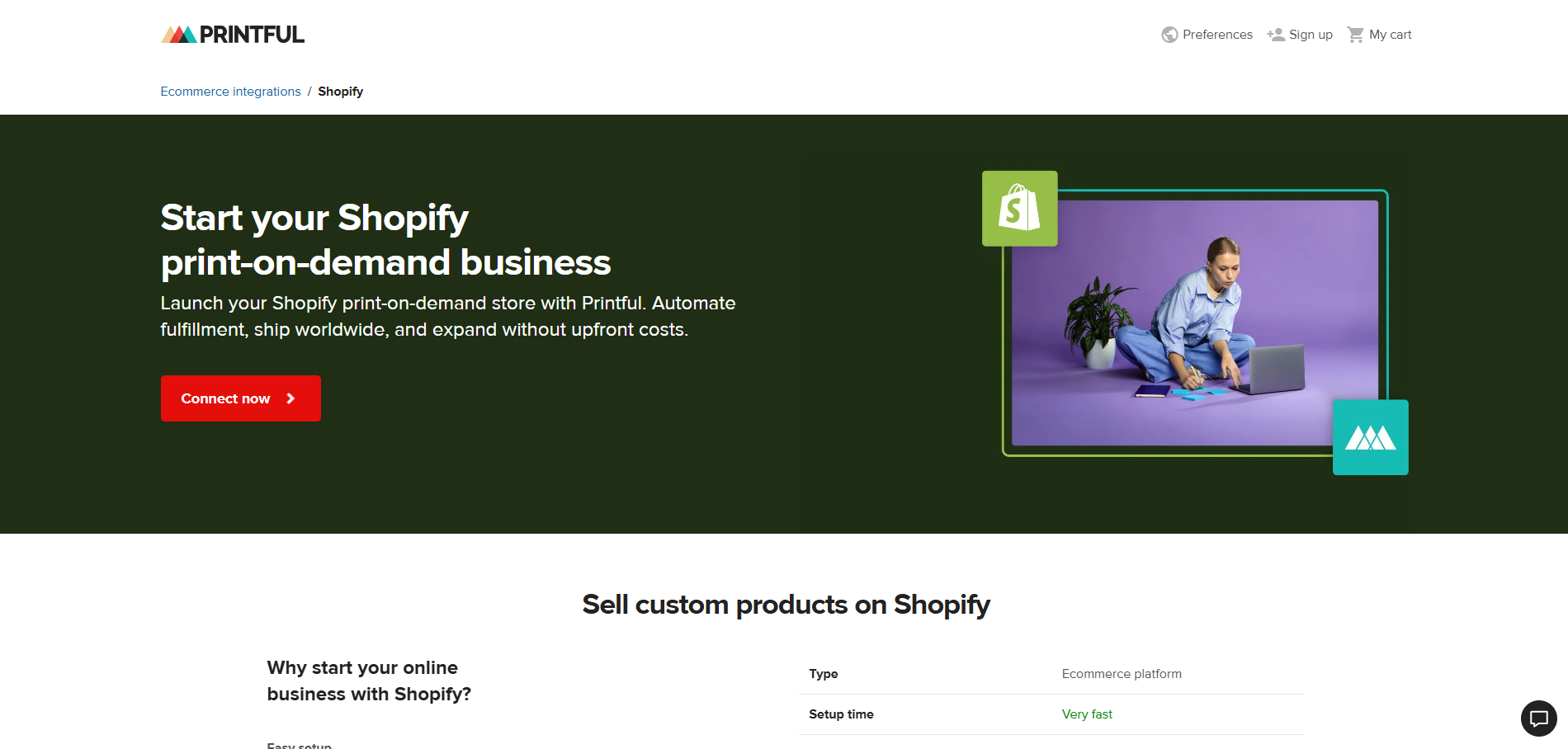

Printful + Shopify is the quickest way to launch a POD business. The integration is seamless, and for brands focused purely on design and marketing, it removes all operational headaches. That said, it’s not ideal for businesses managing their own inventory or wanting more backend control.

Printful + Shopify is the quickest way to launch a POD business. The integration is seamless, and for brands focused purely on design and marketing, it removes all operational headaches. That said, it’s not ideal for businesses managing their own inventory or wanting more backend control.

Cin7 Core (formerly DEAR Systems) fills that gap. With advanced inventory management, automated purchase ordering, and strong multi-warehouse support, it’s ideal for DTC apparel brands juggling SKU variants and wholesale complexity. It also supports integrations with popular ecommerce platforms and shipping solutions, giving ops teams the visibility they need to scale without chaos.

Cin7 Core (formerly DEAR Systems) fills that gap. With advanced inventory management, automated purchase ordering, and strong multi-warehouse support, it’s ideal for DTC apparel brands juggling SKU variants and wholesale complexity. It also supports integrations with popular ecommerce platforms and shipping solutions, giving ops teams the visibility they need to scale without chaos.

Katana stands out again for its ability to handle variant-rich SKUs and multistep fulfillment workflows. If you’re managing both in-house production and outsourcing (say, a third-party printer or embellisher), Katana gives you the tools to orchestrate it all.

Katana stands out again for its ability to handle variant-rich SKUs and multistep fulfillment workflows. If you’re managing both in-house production and outsourcing (say, a third-party printer or embellisher), Katana gives you the tools to orchestrate it all.

Tailor is ideal for brands building custom collections, running limited drops, or managing complex return logic. It allows you to generate dynamic SKUs, map return workflows by sales channel, and adapt your backend to support campaigns, bundles, or wholesale packouts without burning ops time.

Tailor is ideal for brands building custom collections, running limited drops, or managing complex return logic. It allows you to generate dynamic SKUs, map return workflows by sales channel, and adapt your backend to support campaigns, bundles, or wholesale packouts without burning ops time.

Custom Goods and Kitting

For brands that bundle, assemble, or kit products before shipping — like gift boxes, curated product sets, or cross-category ecommerce brands — light manufacturing takes on a fulfillment-heavy shape. You’re not just shipping a product — you’re building it on the fly.

ShipHero is a great option for brands with their own warehouse or 3PL. Its built-in kitting tools, strong pick/pack/ship workflows, and fulfillment visibility make it easy to manage pre-assembly without adding layers of manual oversight.

ShipHero is a great option for brands with their own warehouse or 3PL. Its built-in kitting tools, strong pick/pack/ship workflows, and fulfillment visibility make it easy to manage pre-assembly without adding layers of manual oversight.

Extensiv is the evolution of Skubana, and it brings even more firepower to multichannel brands managing complex fulfillment. With built-in bundling logic, automated order routing, and deep analytics, it’s ideal for high-SKU businesses that need visibility across channels and the ability to build, ship, and report on kits without breaking stride.

Extensiv is the evolution of Skubana, and it brings even more firepower to multichannel brands managing complex fulfillment. With built-in bundling logic, automated order routing, and deep analytics, it’s ideal for high-SKU businesses that need visibility across channels and the ability to build, ship, and report on kits without breaking stride.

Flowspace offers a different angle, focusing on flexible, outsourced fulfillment. If you don’t want to manage your own kitting in-house, Flowspace helps coordinate across 3PLs while still offering operational transparency and inventory control.

Tailor excels in this category thanks to its customizable workflows. You can track inventory at the component level, manage assembly tasks across team members or stations, and get real-time throughput metrics — all from a single system designed to scale with your operation.

Tailor excels in this category thanks to its customizable workflows. You can track inventory at the component level, manage assembly tasks across team members or stations, and get real-time throughput metrics — all from a single system designed to scale with your operation.

How Can I Manage Inventory, Orders, and Production in One System?

Imagine having a single source of truth — one dashboard that shows you what raw materials are available, which production runs are in motion, which orders are waiting on labels, and what’s shipping out today. No more jumping between spreadsheets, Shopify, Notion checklists, and the occasional sticky note to figure out your fulfillment queue.

A unified system eliminates the gaps that cause operational delays. Instead of manually connecting your order management to your production plan — or worse, relying on someone to remember to update the stock count — your software takes care of that in real time. When a product is sold, it deducts components. When a bundle is packed, it updates the system. When you’re low on ingredients, it suggests a PO.

Here’s how you know you’re ready:

- You’re doing double (or triple) data entry just to keep systems in sync.

- You’re getting burned by stockouts or over-ordering because your data is stale.

- You’re not confident your fulfillment team knows what’s ready, what’s pending, and what’s behind.

With the right software, you can unify your stack without overhauling it. Tailor, for example, slots into your current tools and adds just enough structure to keep things humming without slowing you down. It’s not just about visibility — it’s about alignment. Your inventory, orders, and production finally speak the same language.

How Can I Measure and Improve Throughput in a Light Manufacturing Setup?

Throughput is a fancy way of asking, "How fast are we actually getting things done?" In retail manufacturing, this might mean bundles built per day, orders shipped per shift, or even the number of units a single station can finish in an hour.

Start with basic questions:

- Are we meeting demand or constantly falling behind?

- Where do orders stall? In production, labeling, QA, or fulfillment?

- Which products take the most time to assemble or pack?

You don’t need a full-blown MES or lean consultant to get these answers. You just need software that lets you break down production data by workflow. A system like Tailor lets you:

- Track units completed per team member or per workstation.

- Identify chokepoints (e.g., returns processing taking twice as long as expected).

- Forecast labor needs based on order volume.

Once you’re tracking throughput, you can optimize it. Maybe you shift prep tasks earlier in the day. Maybe you change how bundles are staged. Maybe you reassign a team member from low-value QA checks to higher-impact assembly.

The real win isn’t just faster output — it’s predictable, reliable output. And when your system shows you exactly what’s slowing things down, you can fix it before it spirals into a backlog.

Why Composable Systems Win as You Scale

Let’s face it: The way you run your business today won’t be the way you run it six months from now. Product lines evolve, sales channels multiply, and customers demand new packaging or faster turnaround. If your systems can’t keep up, you either work around them or you start to slow down.

Composable software is built to adapt. You start with what you need, maybe just inventory sync and BOM tracking. Then you layer in returns workflows, bundling logic, forecasting tools — whatever your business calls for. The platform expands as you do.

And because platforms like Tailor are API-first, they integrate easily with what you already use — no ripping out Shopify, QuickBooks, or your WMS. You get real-time data, customizable workflows, and smarter operations, without locking yourself into rigid processes.

The alternative? You wait until things break. Then you scramble to implement an ERP that takes 12 months and changes how your entire team works. That’s the trap Tailor helps you avoid.

Ready to future-proof your retail ops and streamline your light manufacturing? Schedule your demo with Tailor today.