Why Reactive Inventory Practices are a Symptom, Not a Strategy

Constant inventory emergencies aren’t just operational noise; they’re signals your system can’t keep up with modern complexity.

Operations teams move from crisis to crisis. They manage emergency stock transfers, expedited shipments, and manual forecast overrides. They use outdated spreadsheets and dashboards that reveal problems only after financial damage occurs.

This cycle of endlessly reacting to inventory problems feels like the price of doing business in volatile markets. When supply chains shift overnight and consumer demand swings wildly, what else can you do but take the hit and soldier on?

Here's the truth: those reactive practices aren't your solution — they're your system's cry for help.

Researcher Lydia Bennett notes in their 2025 study on AI-driven supply chains, “The conventional methods of managing inventory...are increasingly becoming obsolete as AI technologies usher in new paradigms of efficiency, accuracy, and responsiveness.”

Legacy inventory tools were built for a world that no longer exists — a world where demand patterns held steady, where batch updates were fast enough, and where "buffer stock" could smooth over the cracks. Today's reality, shaped by tariffs, multiple sales channels, and competitors that use AI, has shattered those assumptions.

The good news is that a fundamentally different approach is emerging. AI-powered inventory pilots show you can shift from reactive scrambling to proactive orchestration in weeks, not years. No massive replatforming. No risking your entire operation.

This guide shows you exactly why now is the time to launch your first pilot and prove the value of intelligent AI inventory management, starting with the problems you're already fighting today.

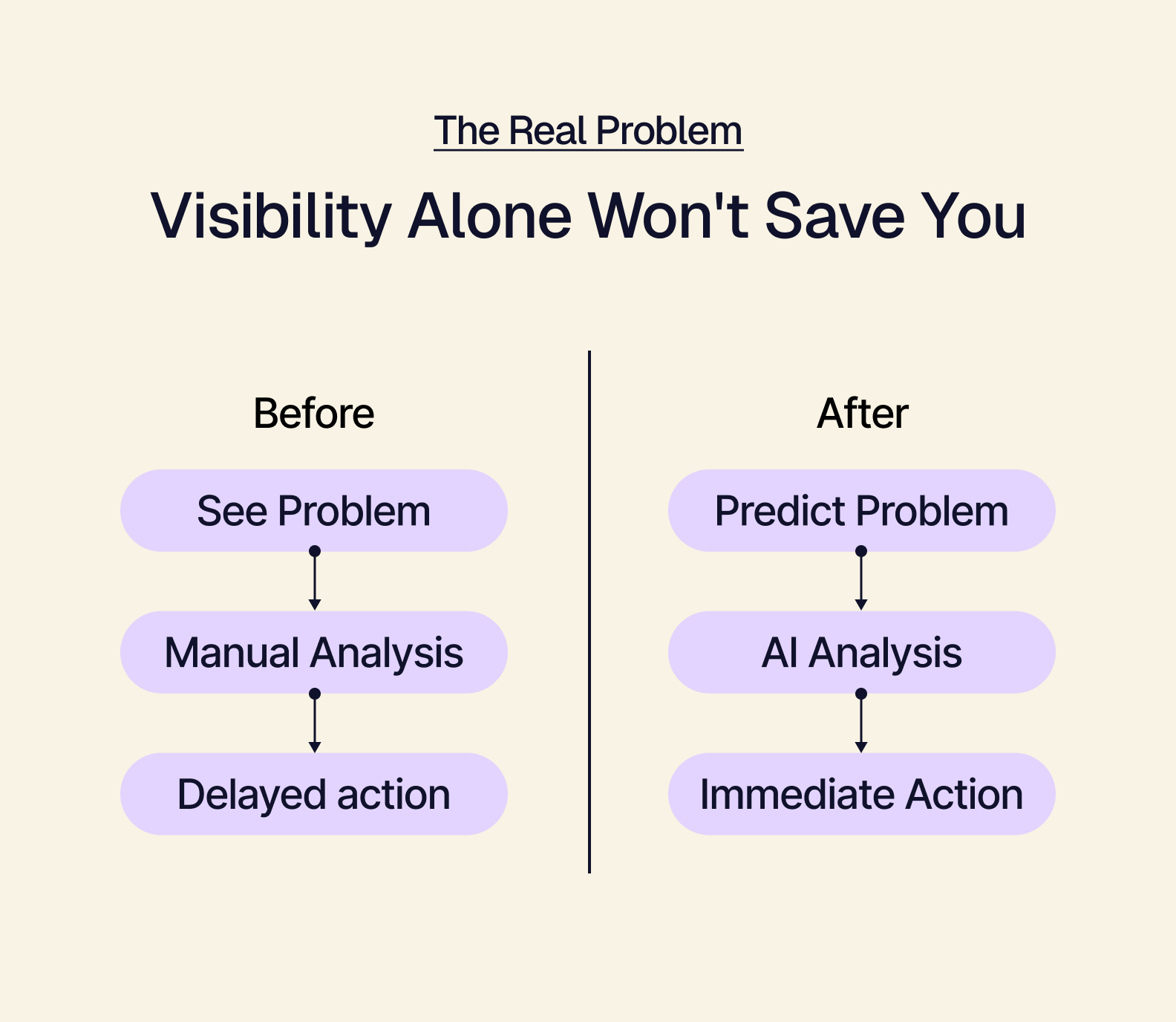

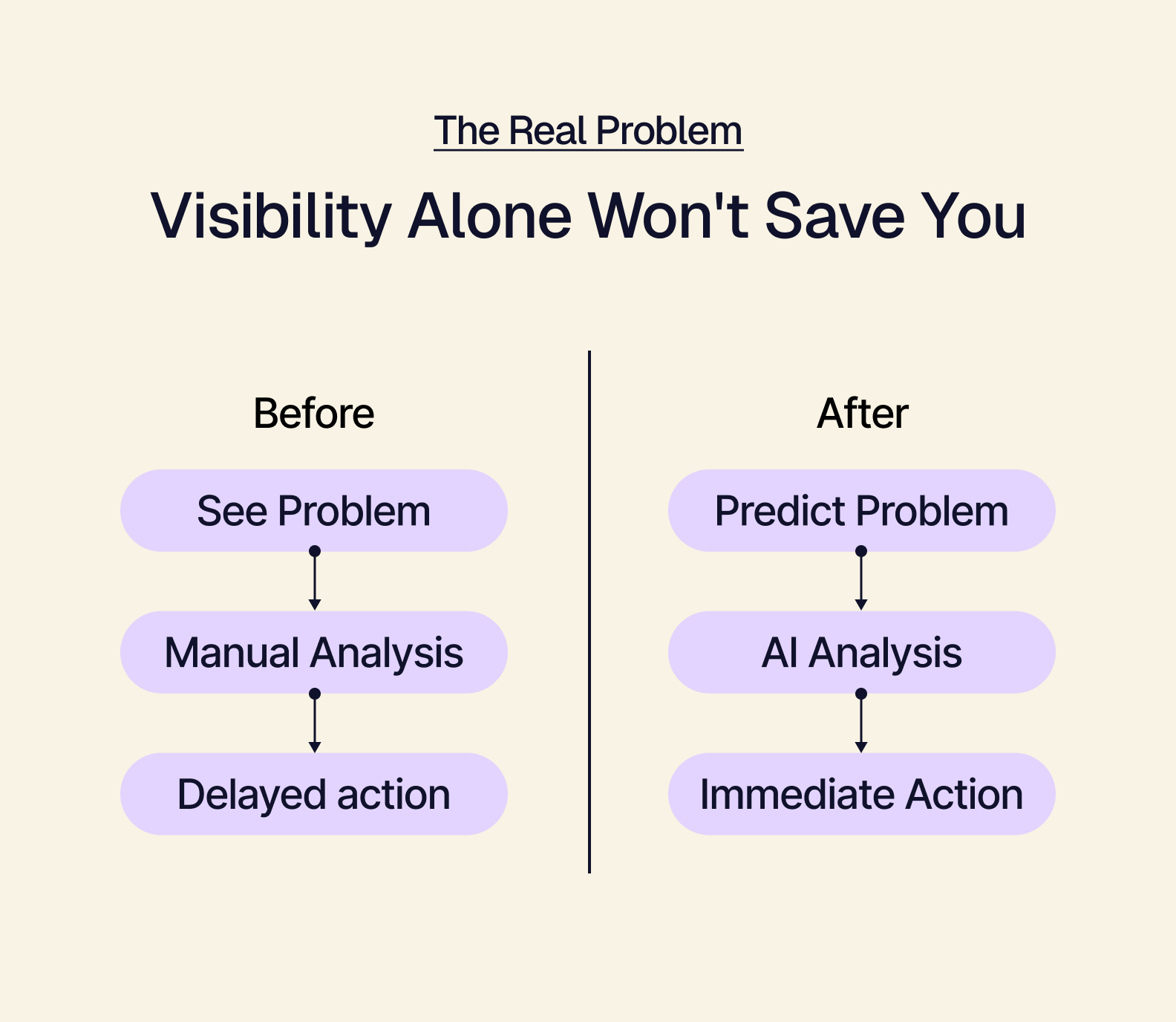

Let’s get beyond visibility and examine the core issue: making decisions.

The Real Problem: Visibility Alone Won't Save You

Visibility without real-time action creates paralysis. Outdated tools target problems without solving them.

The inventory software industry has sold "visibility" as the cure to inventory problems for decades. Yet teams with excellent visibility still scramble through the same emergency transfers. They still miss the same demand spikes. They still watch stockouts happen in slow motion.

Here's why: Visibility without the ability to act is just expensive frustration. Your older systems, built when "fast" meant overnight updates in groups and "complex" meant three sales channels, simply cannot respond to today's speed. They show you where things are going wrong, but they can't correct them; you’re left with alerts and warnings when you need systemic prevention. They generate reports when you need decisions.

Modern inventory challenges don't stem from blindness. They stem from decision paralysis. Demand signals shift hourly, but your reorder process takes days. You spot the trend, but can't override the rules. Every system shows different numbers, and no legacy system can actually do anything about it.

So, what's the solution? Create an AI inventory management pilot.

Why Create an AI Inventory Management Pilot?

AI pilots de-risk transformation by proving value quickly, on real data, with measurable operational impact.

AI-powered inventory management has the potential to reduce your inventory levels by up to 20–30%, according to McKinsey, while cutting procurement spend and logistics costs by up to 5–15%.

Think of an AI inventory pilot as your proof-of-concept lab. It's a focused experiment where you test intelligent orchestration on a small, manageable slice of your inventory. For example, try 5-10 high-velocity SKUs, one distribution center, or a single product category.

Instead of betting your entire operation on theoretical benefits, you're proving real value with minimal risk and maximum learning speed.

Here's what makes pilots so powerful: within weeks, you'll know if automated reorder recommendations actually reduce stockouts. You'll see whether anomaly detection catches issues your team misses. You'll measure exactly how much time your staff saves when the system handles routine decisions. No consultant presentations needed—the numbers will tell the story.

The best pilots start small, fail fast when something doesn't work, and scale quickly when something does. Find out what actually moves the needle for your business, without getting bogged down in data projections and consultation meetings. Treat your pilot the way Fortune 500 big-box stores do:

Key Insights from Retailers

-

Target: AI now covers 40% of stock-keeping units (SKUs), doubling coverage in two years.

-

Home Depot: Launched Sidekick AI 2023, providing support for restocking and shelf-finding using machine learning, enhancing on-hand accuracy and replenishment speed.

-

Walmart: Uses AI to forecast regional demand and redirect products in real time.

Learn more about how Target, Home Depot, and Walmart use AI.

Now that we've seen real-world examples, here's the step-by-step guide to launching your pilot:

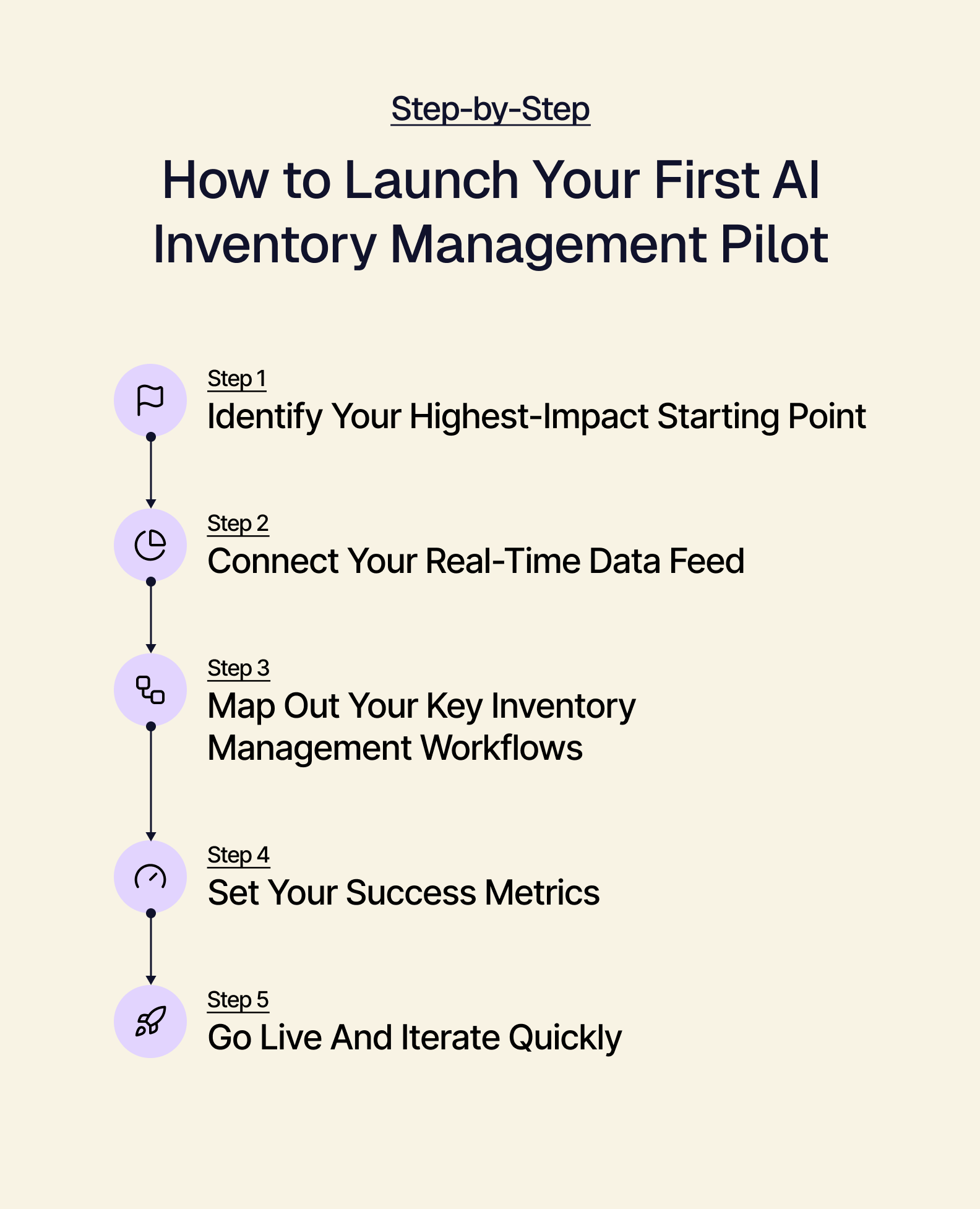

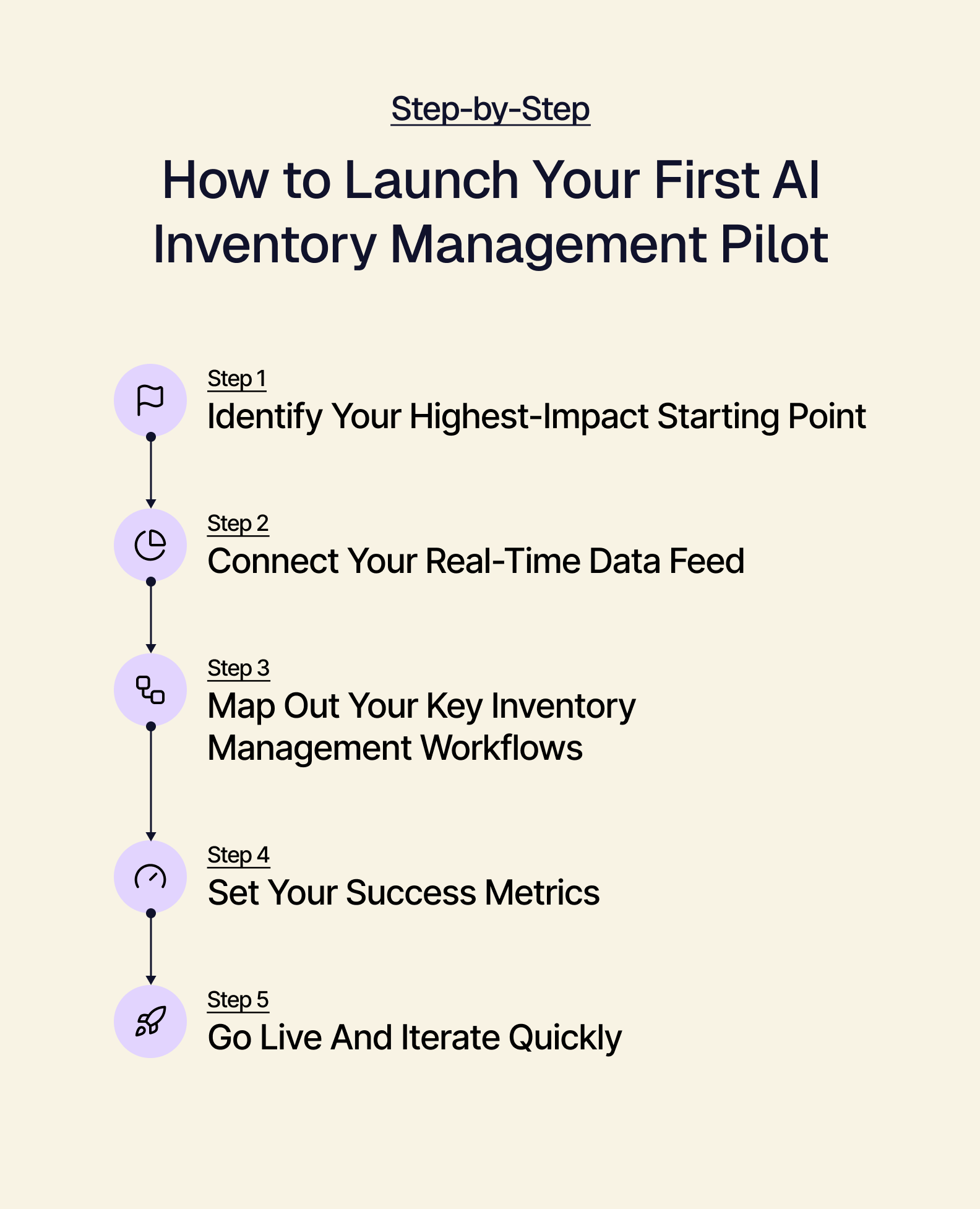

Step-by-Step: How to Launch Your First AI Inventory Management Pilot

A successful pilot starts small, targets real pain points, and delivers fast wins without full replatforming.

Step 1: Identify Your Highest-Impact Starting Point

Look for the inventory challenges that already consume your team's time, such as the SKUs that trigger emergency transfers, the location with chronic count discrepancies, or the category where forecast accuracy hovers around coin-flip odds.

Smart pilots target specific, measurable problems. Here are some examples:

-

Pick 5-10 SKUs with volatile demand patterns, not your entire catalog.

-

Focus on one distribution center with consistently tracked inventory struggles.

-

Choose the product category where stockouts cost you the most.

This focused approach lets you run your AI pilot without risking operational stability.

Manual vs. AI Pilot: The Difference between Passive and Active

| Manual Approach |

AI Pilot Approach |

| “Let's improve inventory management” |

“Let’s reduce stockouts for 10 SKUs by 30%” |

| Months of vendor evaluations |

2-week focused, trackable experiment |

| Enterprise-wide rollout planning |

Single category or location test |

| IT-led implementation project |

Business-led, live implementation |

| Success = system goes live, data gathering begins |

Success = measurable KPI improvement, iterating on new data |

Step 2: Connect Your Real-Time Data Feed

Don't wait for perfect data. AI systems can work with what you have and improve as you add more signals. Start with your highest-value data streams: point-of-sale transactions, current stock levels, in-transit inventory, and supplier lead times.

-

Application Programming Interfaces (APIs): Direct connections to your Warehouse Management System (WMS), Enterprise Resource Planning (ERP), or Point of Sale (POS) systems provide the cleanest data flow

-

Internet of Things (IoT) Sensors: Radio Frequency Identification (RFID), weight sensors, or computer vision for physical inventory tracking

-

Integration Platforms: Software that connects systems (also called middleware) without custom coding

-

Data Streams: Use data streams to collect real-time events from e-commerce platforms and fulfillment systems.

Your AI pilot lives or dies on data quality and speed. Legacy batch updates that refresh overnight can't power real-time decisions. You need live feeds that capture sales as they happen, inventory movements as they occur, and supply chain signals as they emerge.

The integration challenge:

Most teams get stuck here. Your Point of Sale (POS) system talks to one system, your Enterprise Resource Planning (ERP) system speaks a different language, and your warehouse management system lives in its own silo. Building these connections manually is a months-long IT project that kills pilot momentum.

This is exactly why platforms like Tailor exist. Instead of building custom integrations from scratch, you get pre-built connectors to major systems like Shopify, NetSuite, QuickBooks, and dozens of others. The data flows are already mapped, the APIs are already tested, and you can be pulling live inventory data in days, not months.

Step 3: Map Out Your Key Pilot Workflows

Traditional inventory workflows follow rigid rules: when stock reaches X level, reorder Y amount.

Your AI pilot needs to demonstrate smarter, adaptive workflows that respond to patterns, not just thresholds. Map out 2-3 specific workflows where AI can show immediate value through better decisions, faster responses, or eliminated manual work.

| Process |

Manual Workflow |

AI-Powered Workflow |

| Reordering |

Check stock levels daily → Calculate reorder quantity → Submit PO → Wait for approval |

AI monitors continuously → Predicts optimal order timing → Suggests quantity based on multiple factors → Auto-submits for exception-only approval |

| Stock Allocation |

Weekly review meeting → Spreadsheet analysis → Manual transfer orders → Hope it arrives in time |

Real-time demand monitoring → AI identifies imbalance → Recommends transfers before stockout → Tracks execution automatically |

| Anomaly Response |

Notice problem after customer complaint → Investigate across systems → Manual correction → Update spreadsheet |

AI detects unusual patterns instantly → Alerts relevant team → Suggests corrective action |

Step 4: Determine Your Success Metrics

Choose metrics that link directly to business value, such as reduced stockouts, improved forecast accuracy, faster inventory turns, or hours saved on manual tasks.

Here are other metrics to keep in mind during your test:

-

Key Performance Indicator (KPI): One main metric (e.g., 25% stockout reduction)

-

Speed Metric: How fast decisions or actions happen (e.g., 4-hour to 4-minute reorder decisions)

-

Accuracy Metric: Improvement in predictions or counts (e.g., error in predictions reduced by 15%)

-

Efficiency Metric: Time or cost saved

-

Learning Metric: Number of insights or patterns discovered

Step 5: Go Live, Iterate Quickly

Launch day isn't a finish line—it's when real learning begins. Start with a small group of experienced users who understand both the current pain and the potential improvement. These champions provide feedback, catch unusual situations, and help refine the system before broader rollout.

Remember: Every issue you resolve makes the system stronger. The pilots that succeed aren't perfect from day one; they improve faster than the problems they're solving.

Ready to get started? Here's how Tailor makes it easy.

Make Your First AI Inventory Management Pilot Easy! Book a Hands-On Demo with Tailor

→ Tailor turns AI pilot planning into action — helping you scope, connect, and launch in days, not quarters.

You've read the playbook. You know the steps. But between your overloaded team, older system constraints, and the pressure to show results fast, launching that first pilot can feel overwhelming. It doesn't have to be.

Tailor specializes in turning pilot tests into operational reality, without the typical IT project headaches. Our hands-on demo isn't another vendor pitch. It's a working session where we:

Map your specific pilot opportunity. We'll help identify your highest-impact starting point based on your actual pain points and data availability. No generic use cases, only what works for your operation.

Connect your data without the drama. Tailor's composable, API-first ERP and pre-built integrations mean we can tap into your existing systems (WMS, ERP, POS) without months of custom coding. See your real inventory data flowing in real-time during the demo.

**Build your first AI workflow together. **Using Tailor's tools that require little coding, we'll create an actual workflow: whether that's smart suggestions for reordering, detection of unusual patterns, or automatic assignment. You'll leave knowing exactly how it works for your needs.

Define your success metrics and timeline. We'll help you set realistic, measurable goals and show you exactly how to track progress. Plus, you'll get a clear pilot roadmap you can share with your team immediately.

Walk away from our working session with more than ideas. You'll have a set up test environment, a plan for putting it into action, and the confidence that comes from seeing AI work on your actual inventory challenges—not hypothetical scenarios.

Don't let spreadsheet chaos delay progress. Book your AI inventory management planning session with Tailor to start winning in your market.