5 Inventory Management Challenges Solved by AI

5 Inventory Management Challenges Solved by AI

Inventory used to mean guesswork and late alerts. AI delivers real-time insights and proactive decision support.

In the past, you could safely manage your inventory from a reactive standpoint.

But today, you can no longer wait to see what happens before you take action. The current state of the market — including inflation, consumer behavior, and tariffs — has made this not only dangerous, but impossible.

Luckily, there’s a powerful tool at your disposal that serves as the perfect solution to these inventory management challenges. Artificial intelligence helps you move from throwing darts at the wall to confidently making real-time, data-based decisions.

In this guide, we’ll walk through some of the biggest inventory management challenges in today’s industry. We’ll also explain exactly how AI-powered solutions can transform your strategy, taking you to the proactive, forward-thinking place where you need to be.

Doing what you’ve “always done” for inventory management is probably no longer working.

There are a few reasons why.

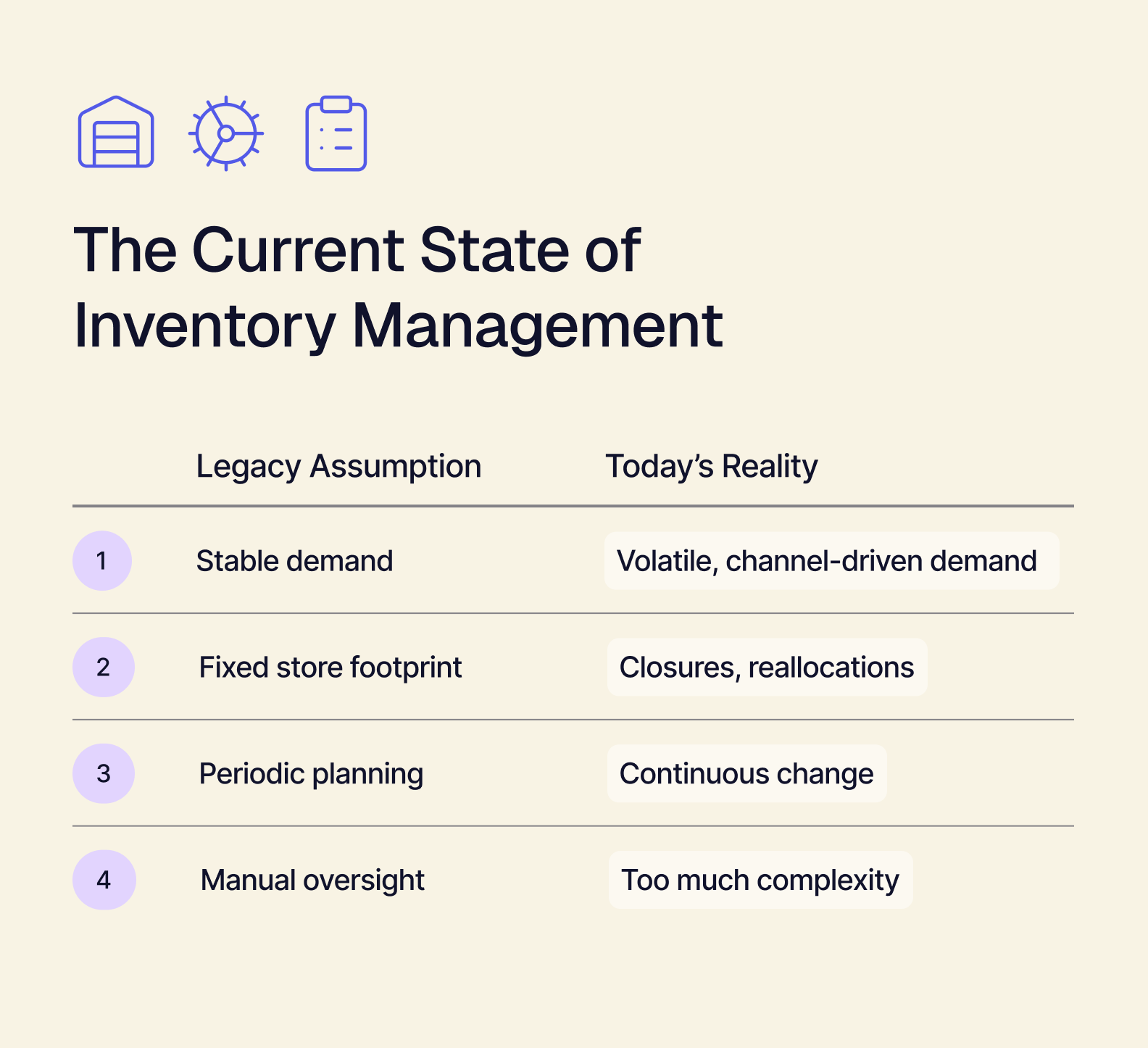

To begin with, legacy software can’t keep up with today’s retail complexity. Inventory tools from an older era assume that:

But retail has massively evolved. Consumer behavior changes fast, creating shifting demand and “live” inventory. You likely sell through a handful of channels. And you can’t be expected to manually monitor all data, especially as you continue to scale and grow.

All of this means your inventory decisions carry more weight.

The current market makes the need for customizable retail applications even more apparent. Inflation is stabilizing. But consumer spending is still cautious, with data from ConsumerWise showing that U.S. consumers plan to pull back their spending in most nonessential categories.

In response, inventory management has to operate as a flexible system. Platforms like Tailor allow inventory data, planning logic, and workflows to continually adapt as customer behavior continually changes, too.

It’s clear that inventory management is much more complex than it used to be. And that means your systems and solutions need to rise to the challenge, scaling complexity in response.

You can address each of these common inventory issues with AI-driven systems, eliminating uncertainty in favor of actionable insights.

At one time, you could use historical data to accurately forecast demand. But this doesn’t work anymore. Last year’s data is unreliable because of different economic conditions or a new channel mix, causing you to sell out or overstock.

AI uses real-time inventory data to update forecasts, factoring in demand shifts across sales channels and allowing scenario modeling (“what if XYZ happens?”). Your forecasts will still be relevant even when conditions change. And the result is fewer stockouts and better pricing strategies.

Retailers like Walmart have invested in AI-driven inventory and forecasting tools to access predictive analytics and better anticipate demand shifts.

When you rely on legacy systems that have fixed reorder points, assumed lead times, and manual overrides, these factors all affect your ability to effectively replenish stock. Eventually, you’re going to find yourself with too much inventory, stockouts, and a big headache.

When AI helps with replenishment, you get the dynamic thresholds you need. Lead-time variability and proactive alerts create a more predictable inventory flow — one where the rules are continuously adjusted to avoid major issues.

For example: Nike’s profits took a hit thanks to excess inventory. So, the company introduced AI-powered tools to better coordinate replenishment with actual supply and demand.

Policies and tariffs have been extremely uncertain over the past year. This uncertainty affects sourcing routes, the cost of goods, and other financial- and compliance-related decisions.

AI can provide continuous policy and cost monitoring so you don’t have to manually track policy updates. Instead, automatically compare possible scenarios. Then make smarter decisions, adjusting pricing and sourcing on the fly when needed. This reduces compliance risk and protects your margins.

Retailers like Best Buy have warned consumers that tariffs would impact the store’s inventory and pricing, demonstrating how unstable policies have a direct impact on inventory planning and management.

Approximately 15,000 brick-and-mortar retail stores closed across the U.S. in 2025. In this situation, it’s all too easy to end up with inventory stuck in the wrong places, ultimately impeding profitability.

AI enables smarter inventory reallocation, location-aware demand forecasting, and optimized fulfillment across less locations. The impact: more profitable downsizing, with intentional transfers and better omnichannel fulfillment.

Social commerce doesn’t follow traditional planning cycles. You may not be able to predict a sudden spike in demand driven by influencers — and by the time you notice, the viral moment could already be over.

AI can sense demand in real-time, allowing you to respond in the moment to trends that will quickly burn out. You’ll stay on top of viral moments without having to overbuy or overcommit.

Beauty brands that sell through TikTok Shop often experience these types of demand swings because of influencers driving viral sales, underscoring the need for inventory systems that can bring your attention to demand signals as momentum builds.

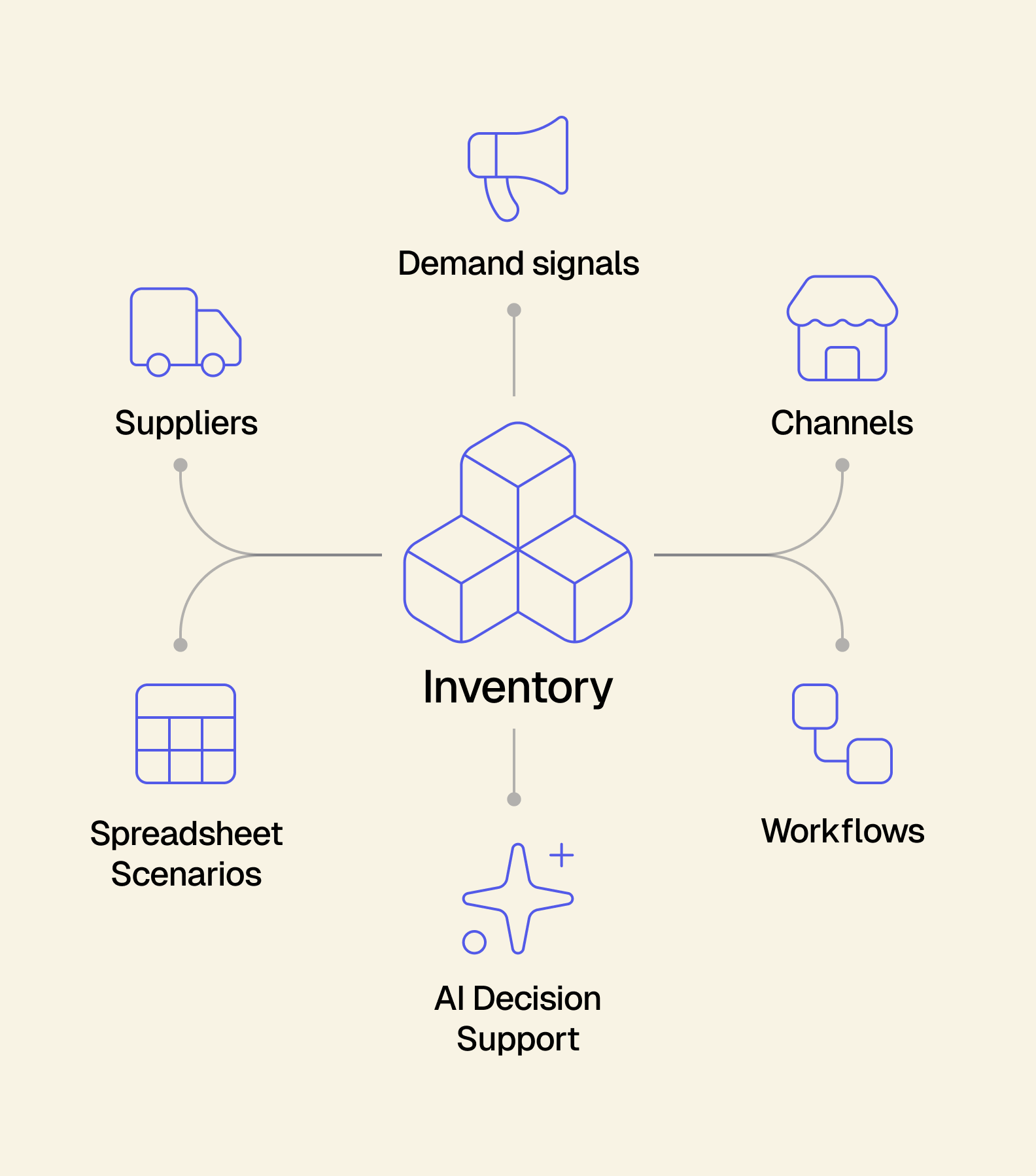

Inventory management is a system, not a feature. And in the real world, it works best when demand, supply, and workflows are connected to enable proactive decision-making.

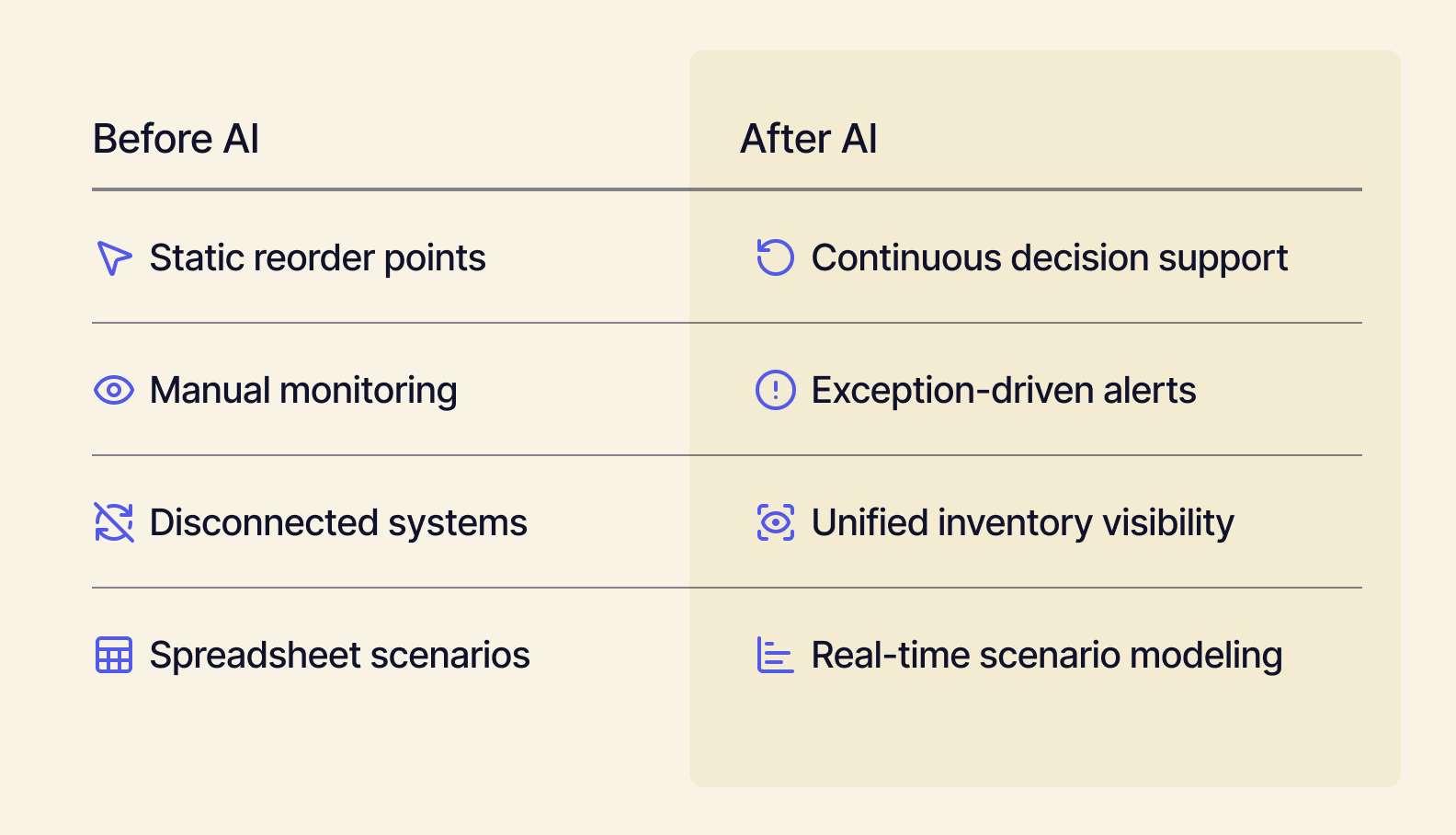

Legacy inventory management tools have fixed reorder points. In other words, they only make decisions in specific situations, like when stock has run out.

AI-driven systems continuously re-evaluate demand, inventory movement, and risk signals so you can make decisions proactively.

This kind of continuous decision support depends on centralized inventory data — an approach platforms like Tailor are built around.

A static inventory view isn’t good enough. The information you’re working with will almost always be outdated.

Instead, you need unified inventory visibility: a single source of truth, with real-time updates and multi-location support. This gives you peace of mind without having to manually reconcile numbers across systems.

Legacy systems force you to wait to react until after a stockout or overstock occurs.

But artificial intelligence is capable of generating and comparing scenarios in real-time. Use a centralized platform like Tailor to model theoretical supplier delays or demand spikes so you can plan intentionally, knowing every decision is backed with accurate data.

At one time, your team may have spent precious hours poring over reports for items at risk… but still missing overstocks, low-stock, or other signals until it was too late.

Save time and manpower by letting AI flag the “exceptions” that matter most to you, whether that’s excess inventory risk or possible stockouts. AI can surface these potential issues in real-time so you’re able to step in before problems escalate.

Rigid structures and pre-defined rules require a lot of manual work anytime you want to make a change (like adding a new supplier or channel).

That’s why you need a low-code, flexible system that can adapt to your business. For example, Tailor’s configurability lets you easily build and modify workflows. If you want to change processes, you should be able to without breaking the automation.

As inventory risk remains uncertain, retailers need early visibility — which is exactly what AI enables. And with retail complexity also increasing, systems-level design matters more and more.

Tailor’s centralized platform, configurable workflows, and real-time inventory visibility provide exactly what you need to confidently address today’s inventory management challenges. Book a demo to see for yourself how Tailor’s AI-powered platform enables better inventory management.

AI creates a system that continuously monitors and adapts, giving you what you need to make smart, proactive inventory decisions.

AI tracks real-time demand shifts across channels and scenarios so you have accurate forecasts even in turbulent markets.

No, not at all. Any size retailer can benefit from flexible, AI-driven workflows to help save time and prevent stockouts or overstocks.

AUTHOR

Abby Nitta