Why 2026 Demands a New Inventory Management Playbook

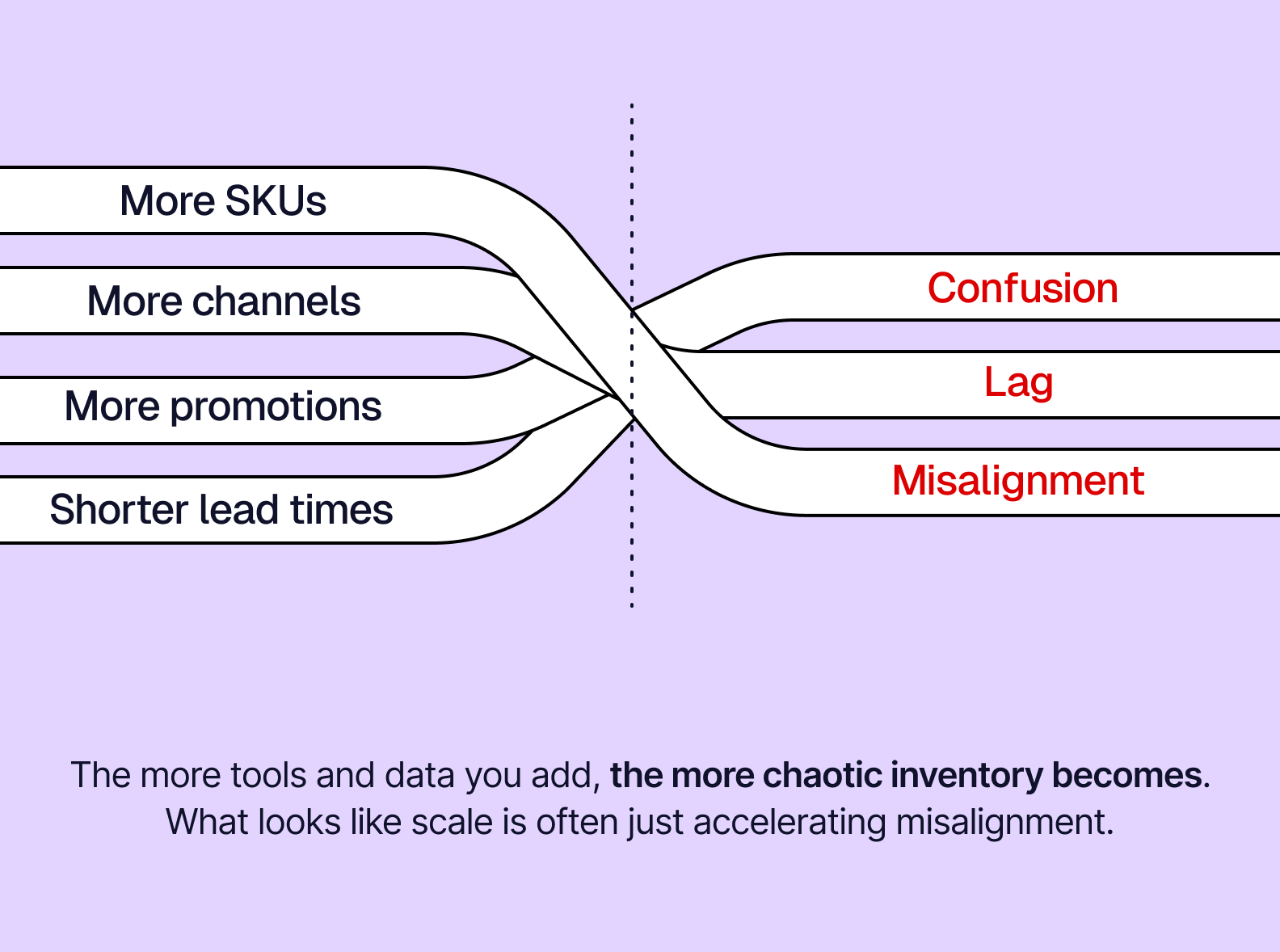

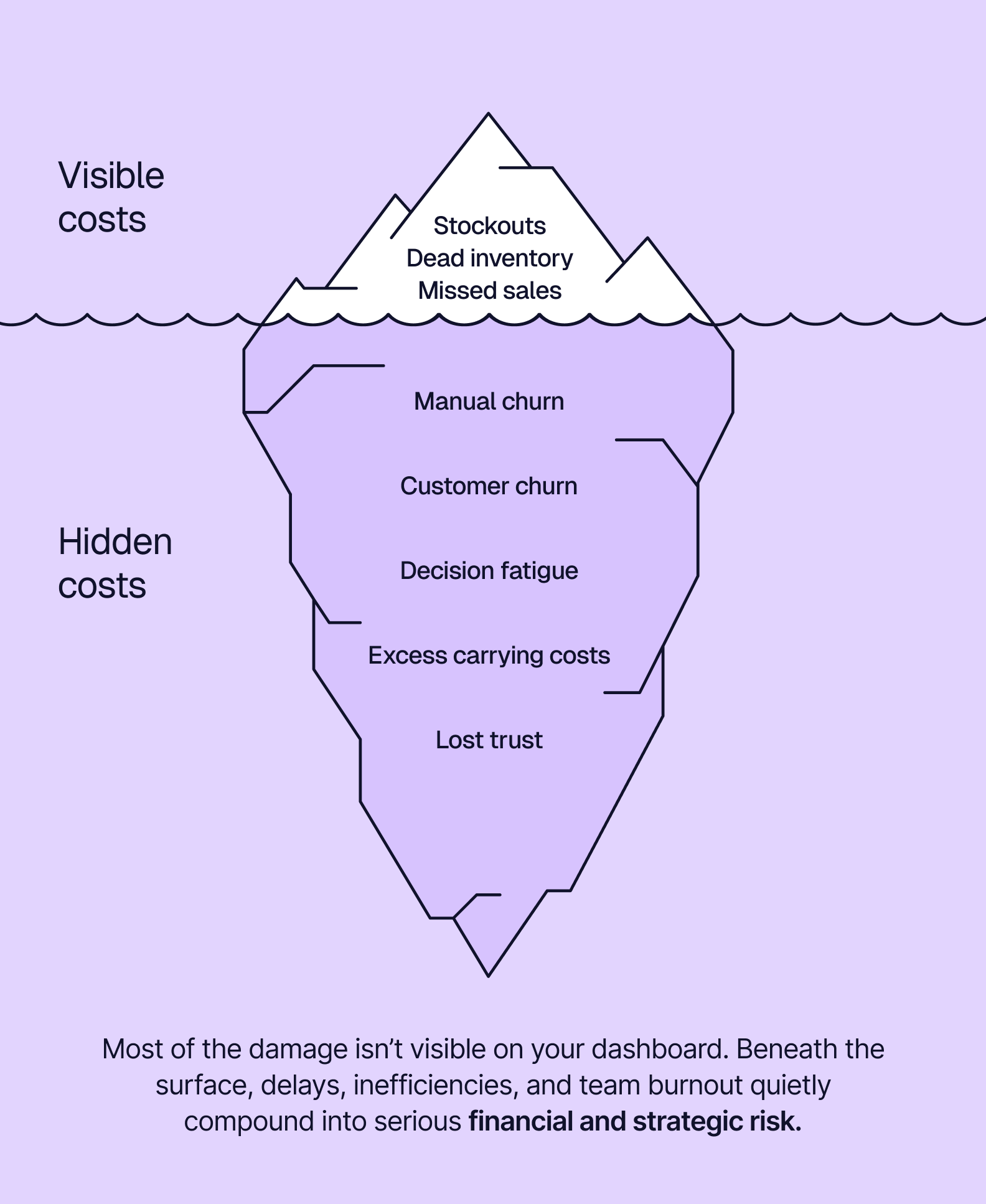

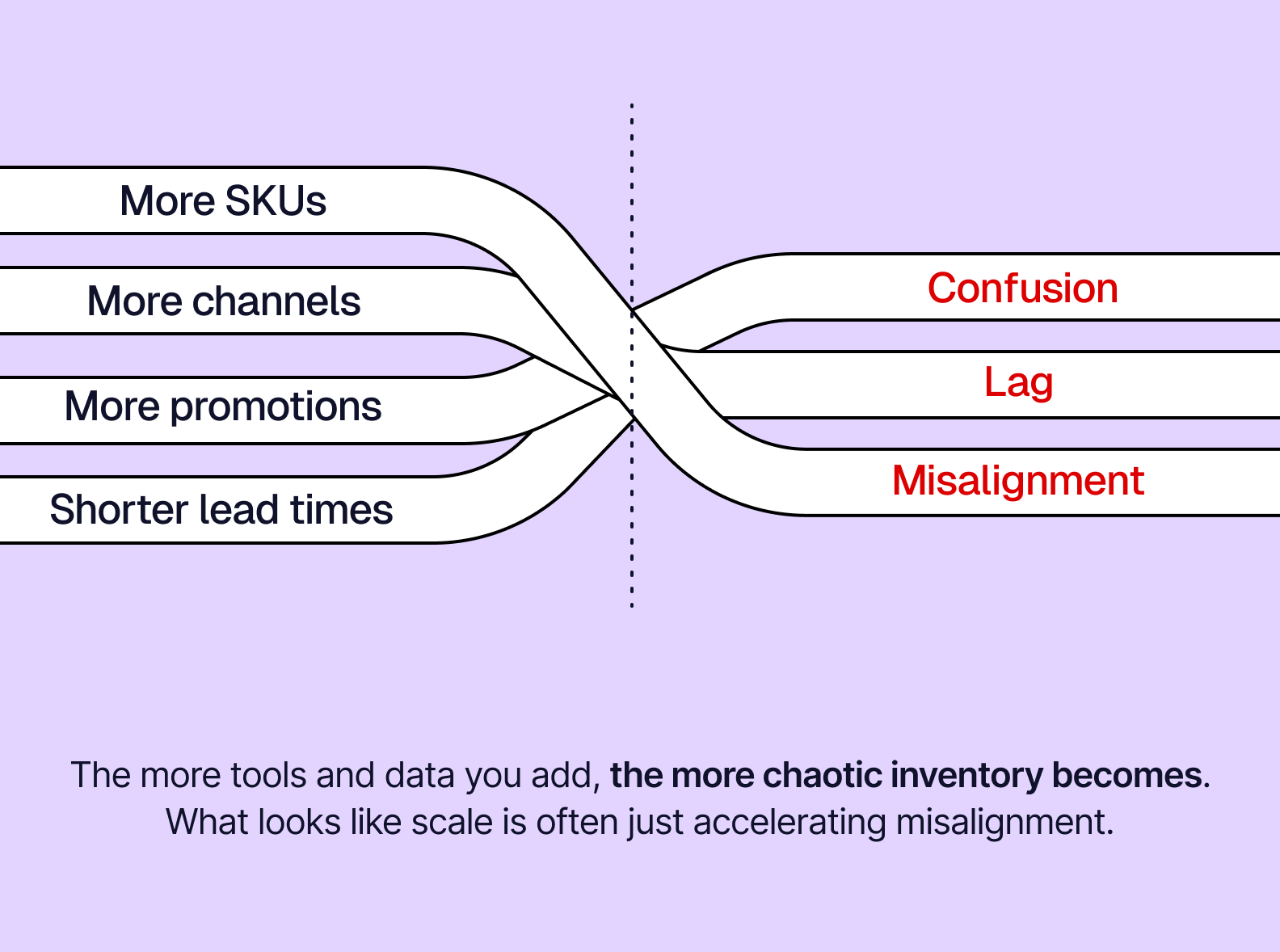

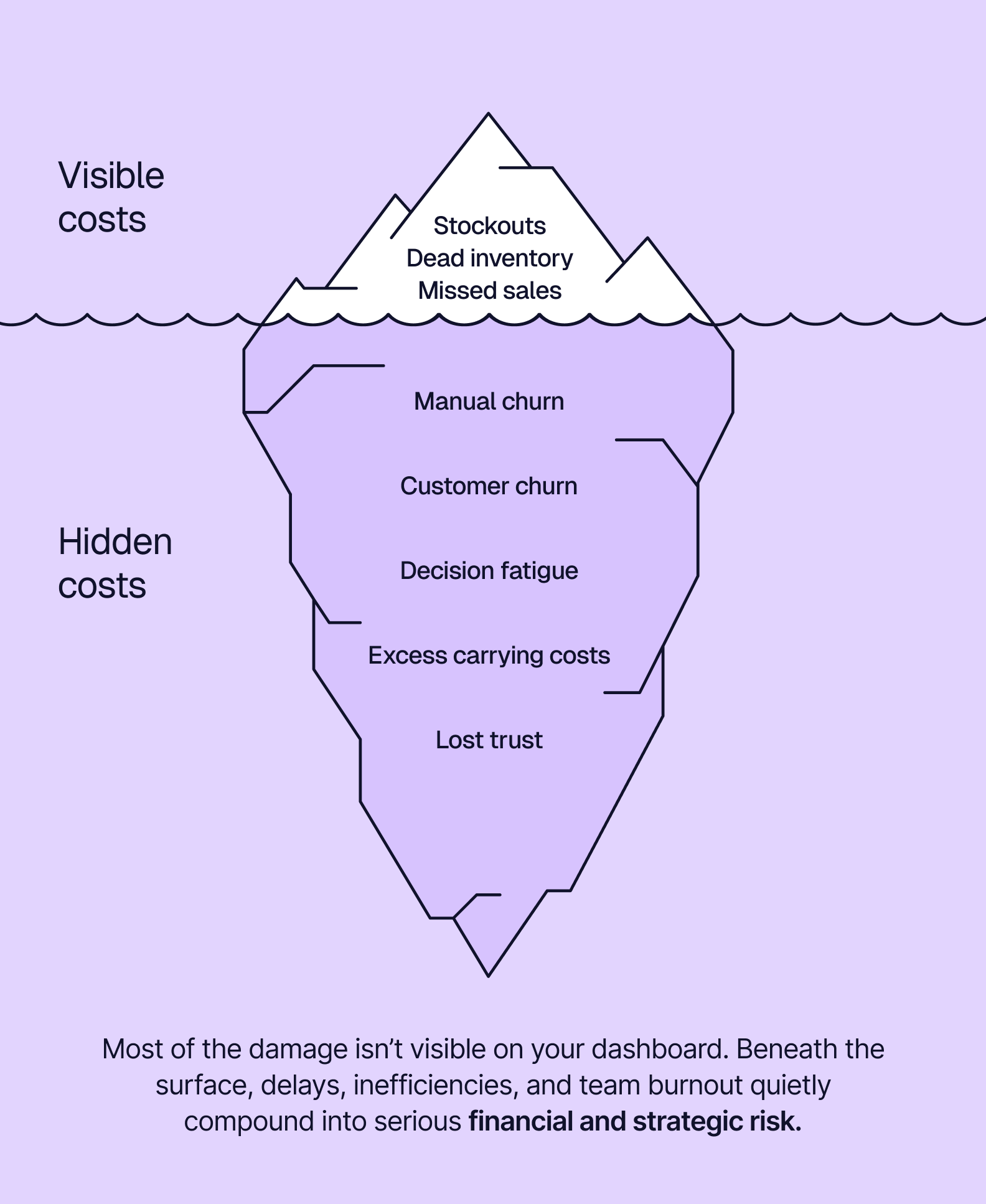

You’ve invested in countless tools to solve your inventory management problems: enterprise resource planning (ERP) systems, demand planning software, even data teams. But for some reason, your inventory problems continue to grow.

Stockouts wreck what were supposed to be high-conversion promotions. Overstock undercuts your margins. Spreadsheets balloon and unwieldy process shortcuts dominate your workflow. You’ve got more data than ever, but making the right decision feels impossible.

Your tools help you spot issues like missed forecasts, late shipments, and warehouse imbalances — but it's already too late to fix them. Each delay loses customers. Each error ties up money you can't afford to lose.

Meanwhile, your processes become more complex: new products, extra sales channels, and fewer people to help you handle it all. Your systems just weren’t designed to handle this level of volatility. But you shouldn’t have to explain why key products are struggling and justify why inventory can’t be sold.

What you need is a real solution, a way to break the cycle.

A study of about 1 million products in 100 stores found that 60% of inventory records were inaccurate — and working quickly to solve them could boost your sales from 4-8% in the short term. The question is “How do I even begin to solve this?”

Common sense would indicate it’s best to just work around these inventory issues; everyone else is doing it (seemingly)! But taking these problems head-on can set you up to outpace your competitors. Why sit and spin your tires when you could drive your business forward?

AI-assisted inventory management offers a more adaptive, data-driven way forward.

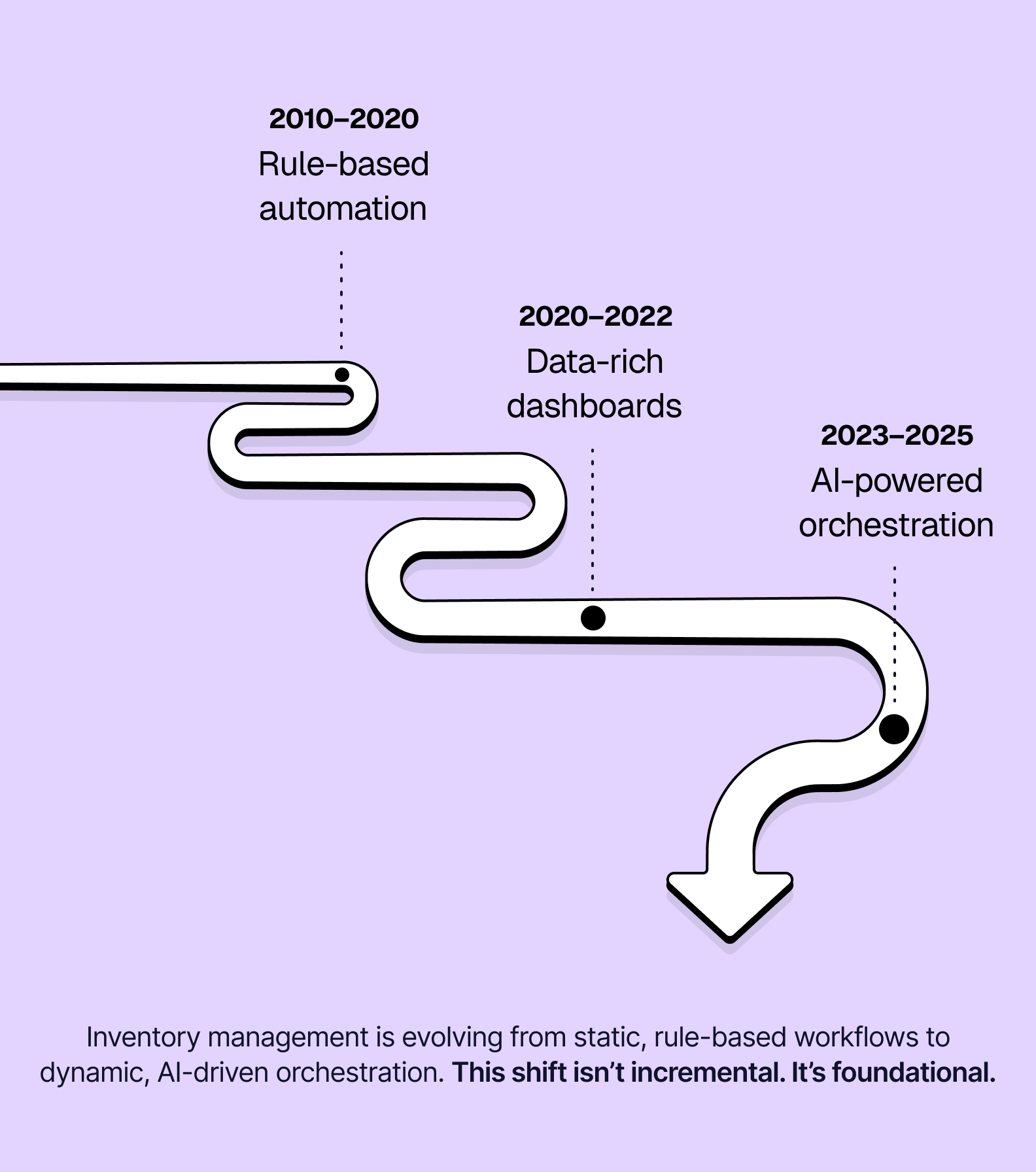

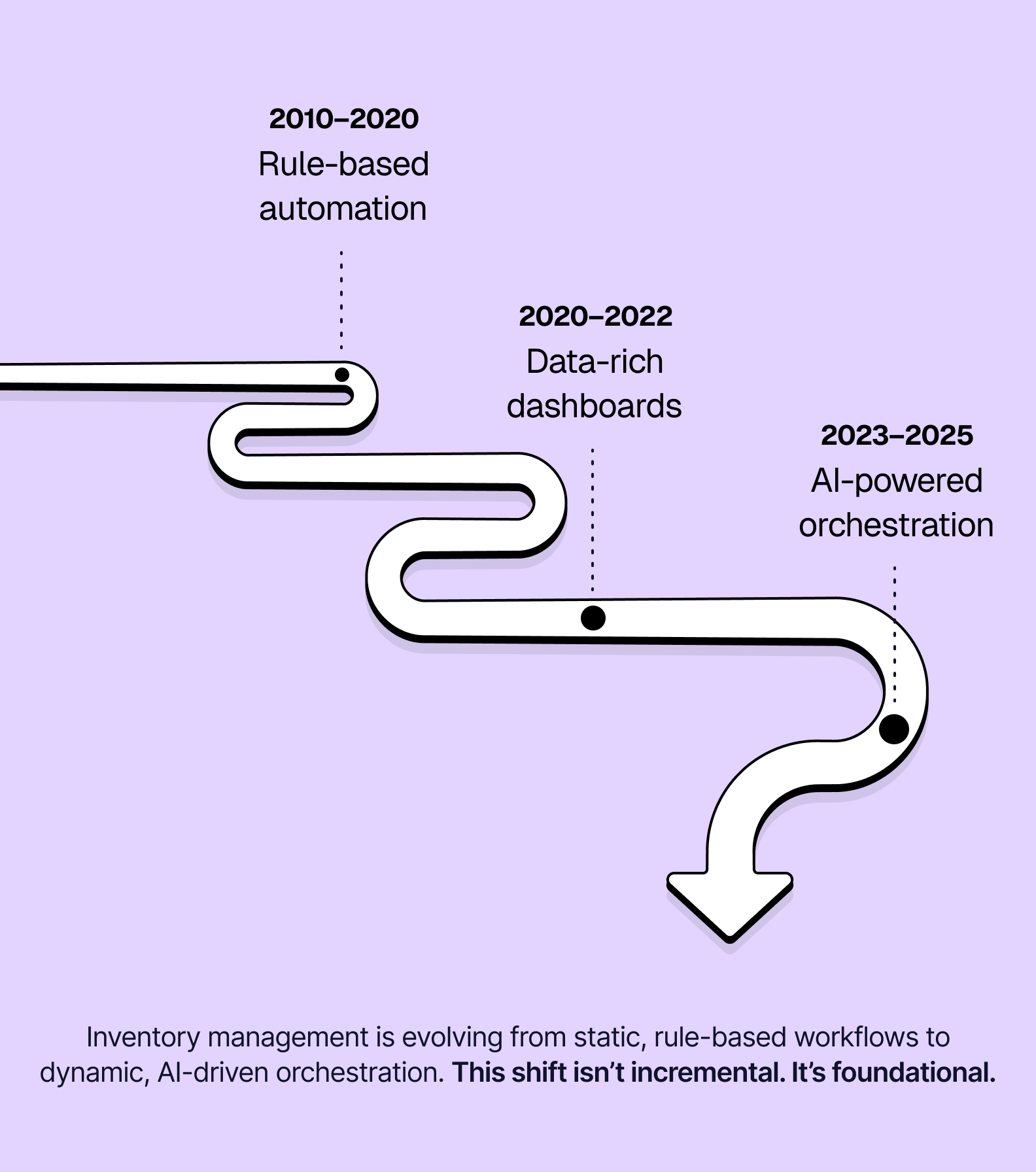

What’s Changed: The AI Moment in Inventory Management

AI shifts from fixed automation to flexible intelligence that handles changes well.

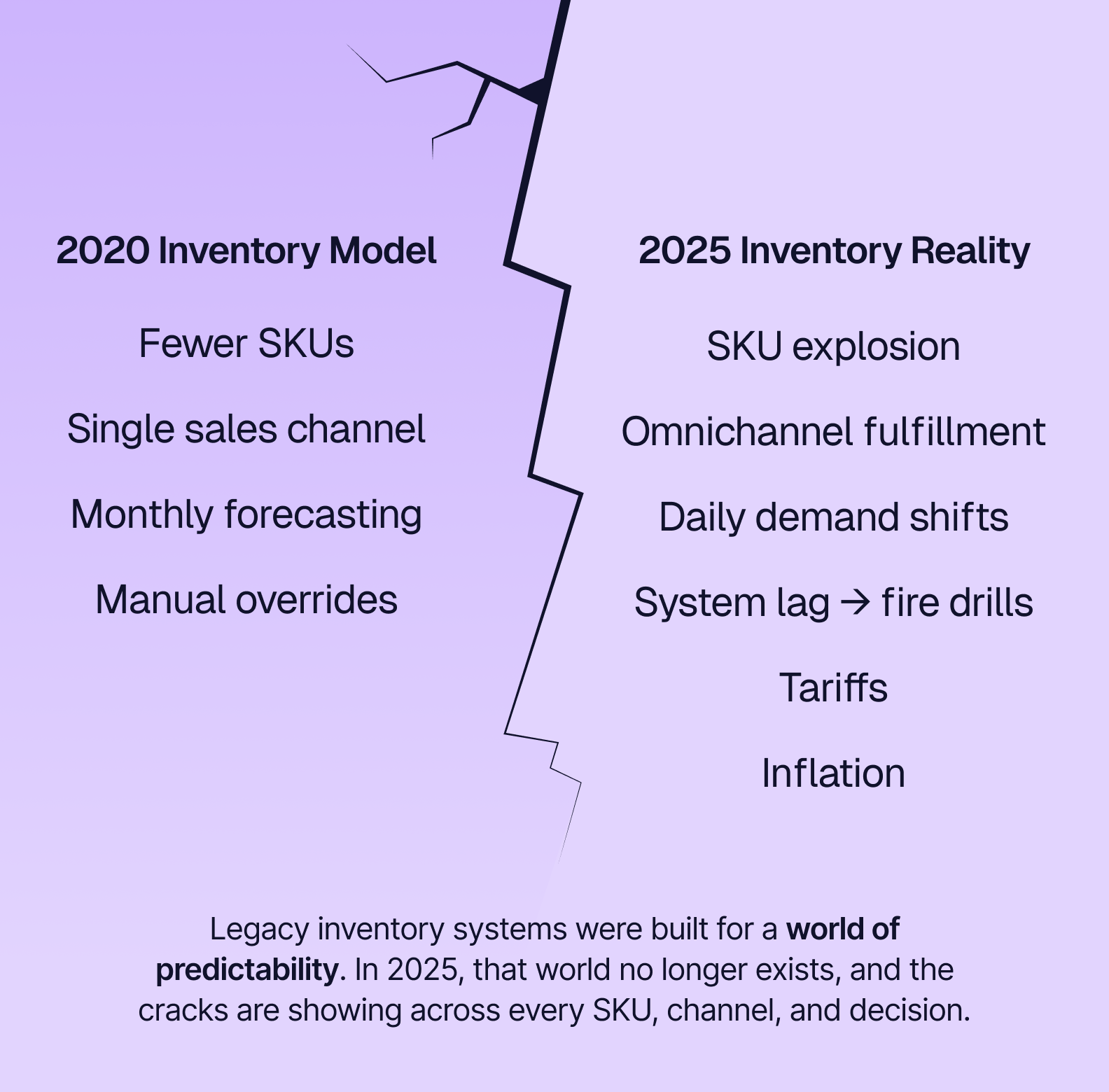

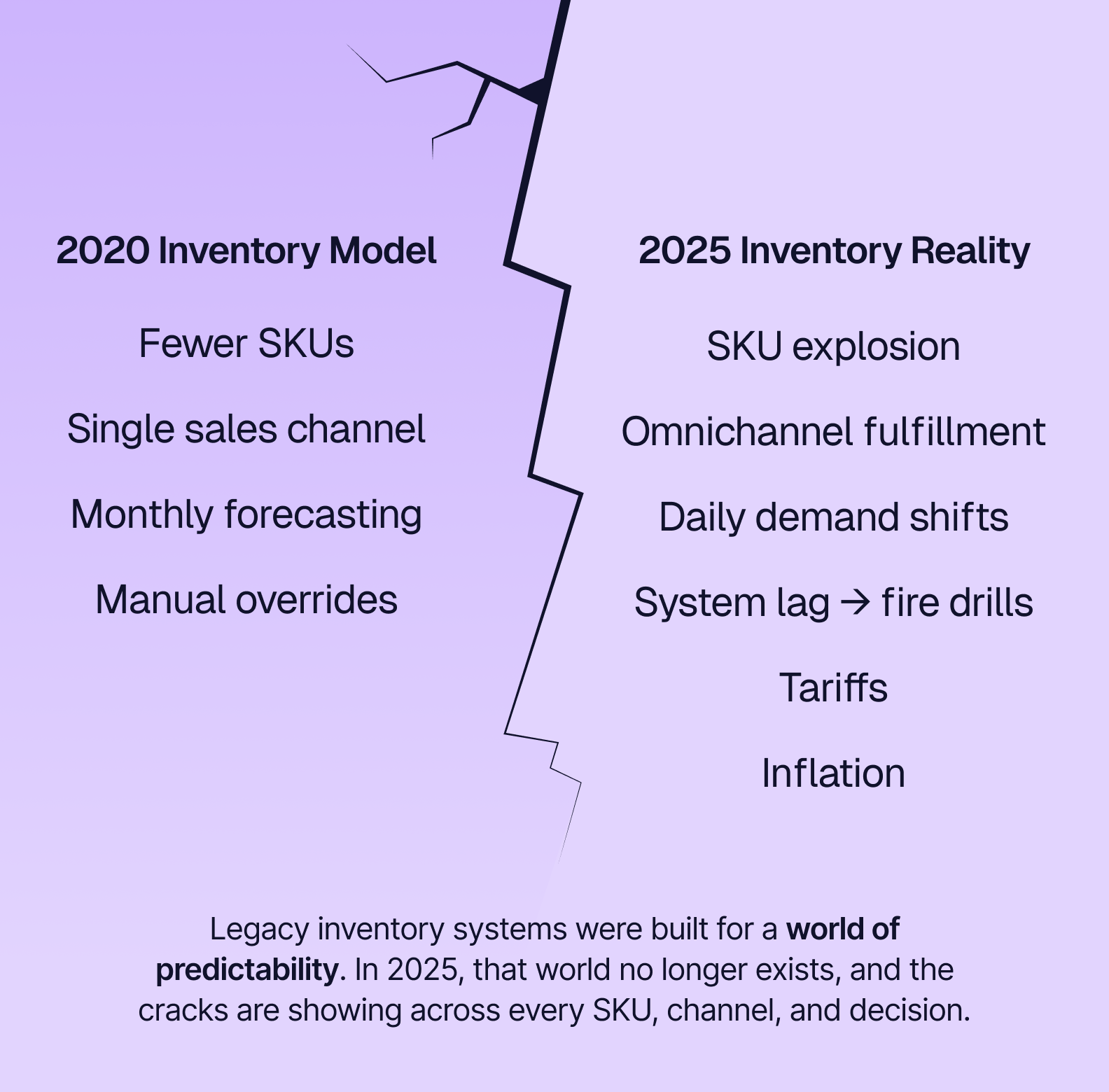

Until recently, most teams handled inventory the same way: automate predictable tasks, keep extra stock for unpredictable ones, and use fixed rules. But in 2026, that approach is outdated.

Changes are now the norm, not the exception. Automation alone can’t adapt fast enough. AI inventory management helps you shift from automation to intelligence. From rules to reasoning and static systems to self-improving processes. AI enables flexible, API-driven decision-making that adapts to near real-time data — reshaping how decisions are made.

Trends Driving the Urgent Need for AI Inventory Management in 2026

The market for AI in inventory management is projected to grow from $7.38 billion in 2024 to $9.6 billion in 2026, at a 30.1% compounded growth rate. If this growth continued at the projected pace, it could reach $27.23 billion by 2029.

More broadly, the global AI market will expand from $279 billion in 2024 to $1.81 trillion by 2030, at a 35.9% annual growth rate.

Those numbers aren’t just hype, they reflect frontline pressures:

-

Retail and online sales growth. As digital stores and convenience shops increase, demand signals have grown. The AI market is growing to meet that demand.

-

Supply chain changes. With regular disruptions, labor shortages, and shipping delays, fixed systems can't keep up. Integrating AI for forecasting and instant responses is essential for your business to compete.

-

Limits on operational growth. Companies with small teams and more products are using AI to manage large amounts of data and fast decisions, keeping growth manageable and costs low.

-

Leading competitors. Big retailers like Walmart, Target, and Home Depot are investing heavily in AI systems. These systems allow billions of flexible inventory decisions, setting new standards for quick and accurate responses.

AI in inventory management is no longer optional. It's the backbone of operations for both survival and growth in 2026.

From Reactive to Strategic: How Inventory Leaders Are Evolving in 2026

Replace rigid workflows with dynamic systems that adapt through feedback.

Legacy tools trained us to think technically — adjust order points, react to differences, and add extra stock for uncertainty. But the companies winning in 2026 are getting beyond legacy tools and transforming the way they think. They’ve stopped managing inventory as a fixed process and started orchestrating it as a dynamic system.

These changes are a distinct shift from a purely technical approach: opting for operational, behavioral, and strategic problem solving.

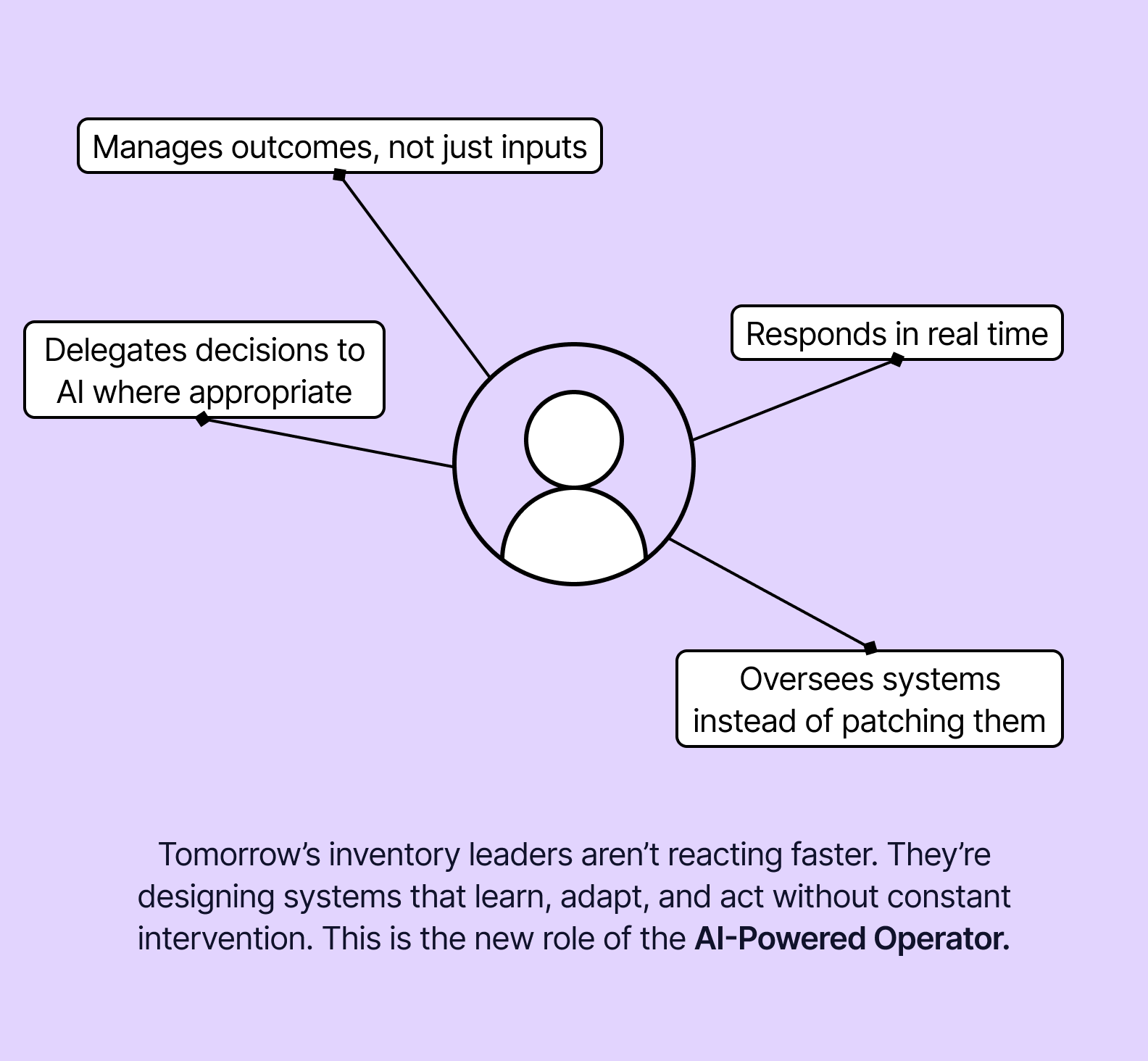

What It Means to Think Like an AI-Powered Operator

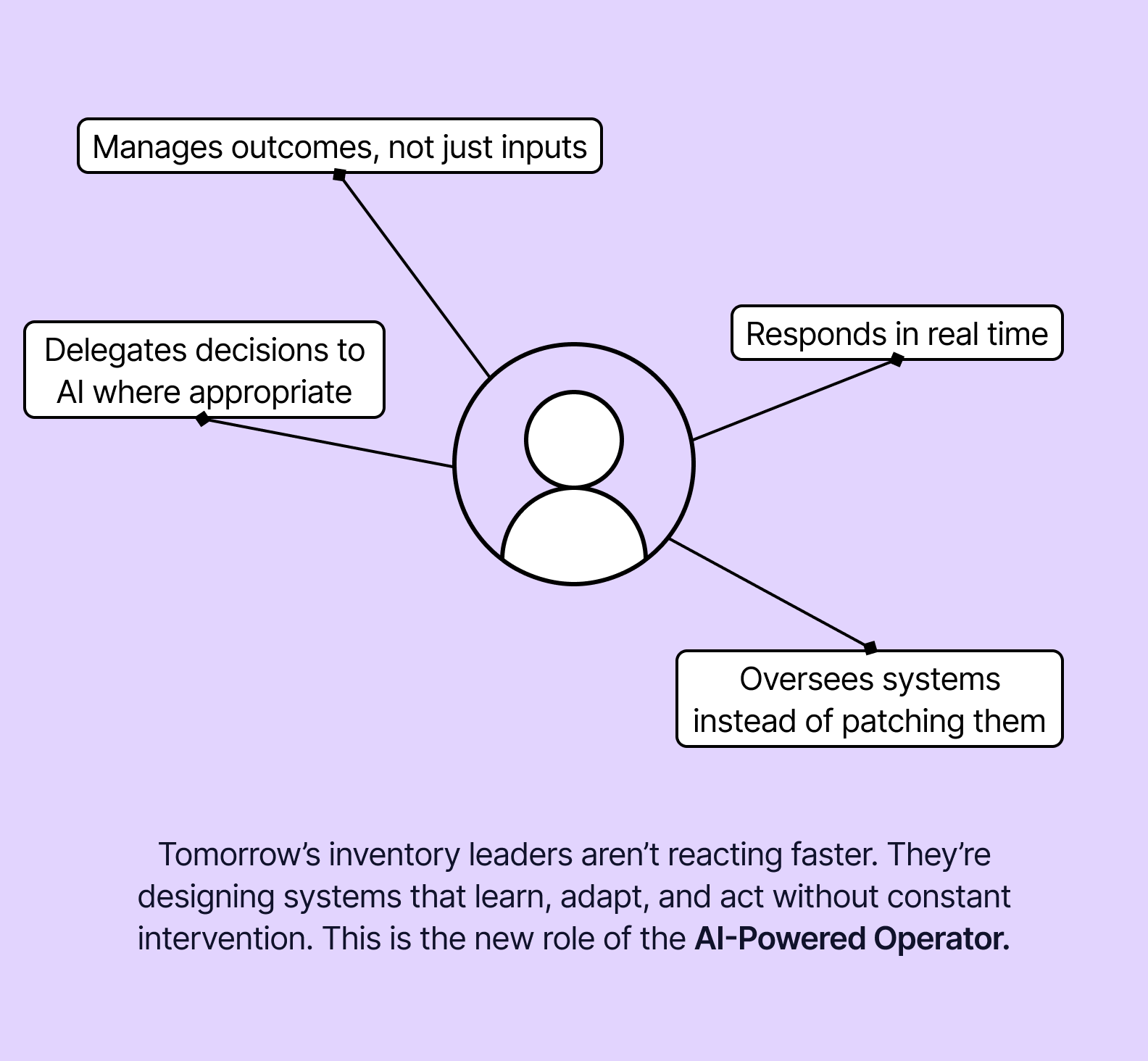

Today’s most effective inventory leaders no longer define success by how accurately they follow the plan. Instead, they define it by how quickly they adapt when the plan fails.

How can you start this shift in your own work flow? Start with how you see your role.

Instead of managing inputs like forecasts, products, and orders; manage results: product availability, sales speed, and efficient use of money. Focus on highlighting the most important signals in your system and partner with AI so it can intelligently evolve with your workflow.

Beliefs That Are Holding Teams Back (And What Replaces Them)

The hardest part of this transformation isn’t the tech. It’s unlearning habits and thought patterns that make sense in a legacy tool world.

Here’s some examples of how inventory leaders are shifting their approach:

| Outdated Belief |

New Mindset |

| "I need more data." |

"I need better signals." |

| "Forecasting is always guessing." |

"Prediction is a system. Systems can improve." |

| "Extra stock protects us." |

"Too much stock hides the real problem." |

| "Automation is risky." |

"Manual decision-making is risky and slow." |

Teams using the old approach try to fix signal issues with process changes. Your workflows aren't broken—they were designed for conditions that no longer match reality.

Adopting AI-driven signals can bridge the gap to a better way to problem-solve.

What High-Performing Teams Are Doing Differently

The best operators in 2026 aren’t more resourced, they’re expert adaptors. Here’s how can become one:

-

Automate simple decisions. Use AI assistants to streamline simple decisions — from reorder triggers to event-based allocations — while maintaining human oversight.

-

Use unusual events as learning opportunities. An unexpected increase isn't a crisis, rather it's a chance to investigate, adjust, and improve the system.

-

Deliver faster with better restocking. Instead of using old reorder points, teams forecast for each product, location, and sales speed. They update daily, not monthly.

-

Run pilots like product teams. From replenishment logic to demand forecasts, changes are tested in small slices before being rolled out company-wide.

One of the biggest changes you’ll experience is in culture: from feeling like you have to be a control freak to working more organically with your team and your tools.

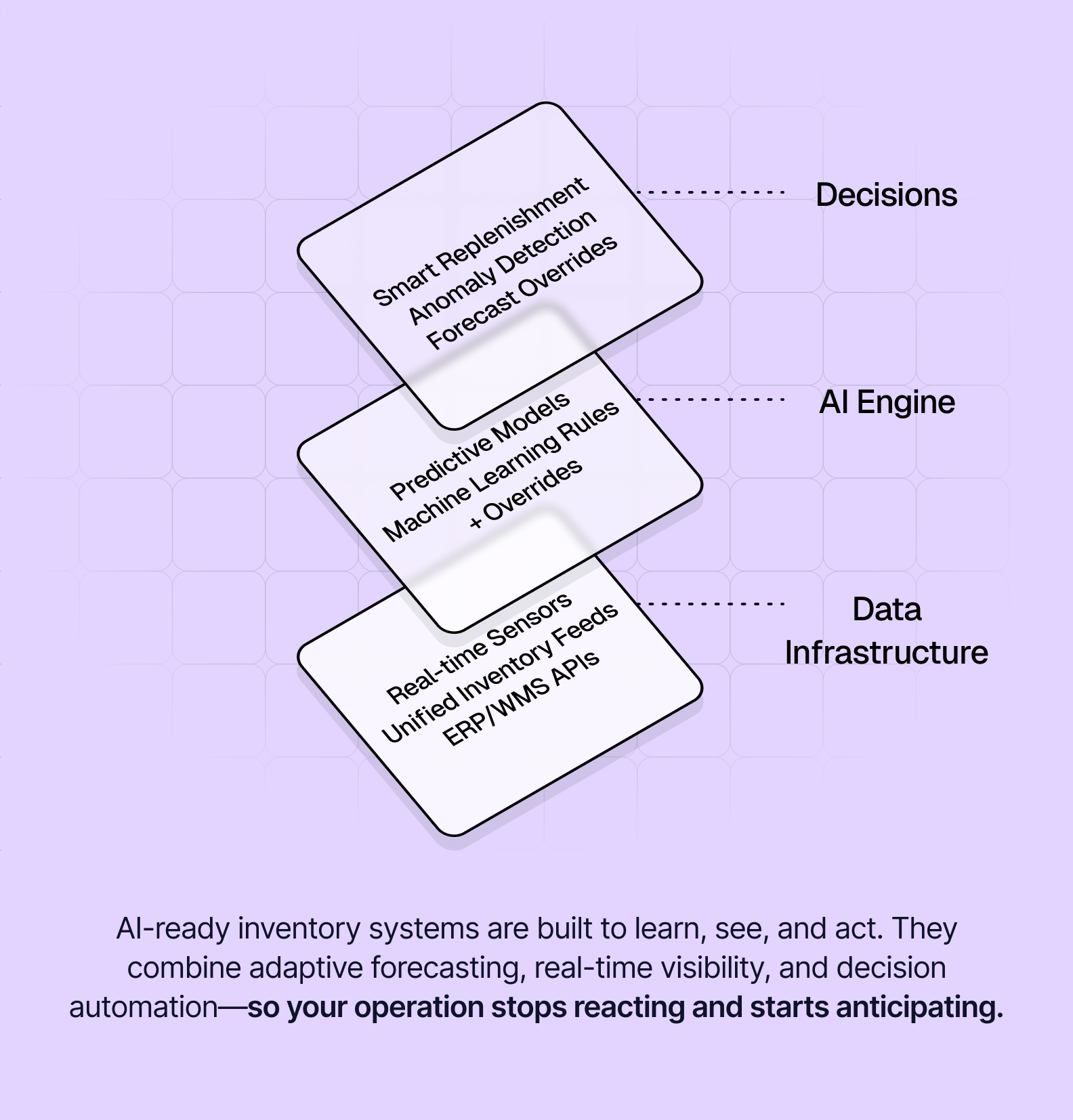

What an AI-Ready Inventory Management Stack Looks Like

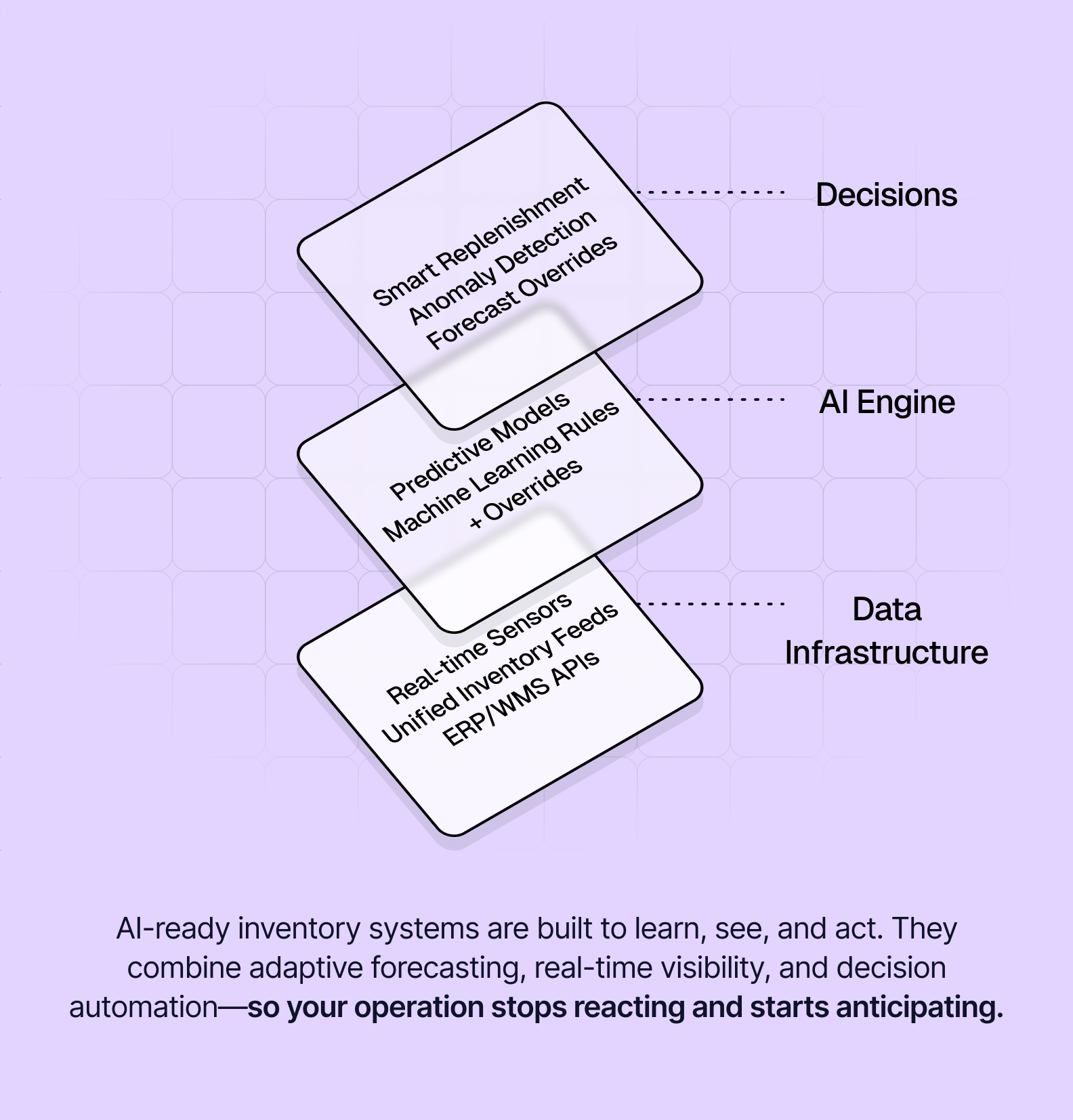

Modern inventory systems combine flexible forecasting, instant visibility, and targeted automation.

Most inventory systems weren't built for smart thinking — they were built to record data, not analyze it. That's why adding AI to old tools rarely works; you need a system created for modern problem solving.

Forecasting That Learns and Adapts Over Time

Traditional forecasting uses fixed rules: last year's sales, seasonal adjustments, and set reorder points. AI forecasting is different and adapts over time through contextual feedback and real operational signals.

Modern systems take in many instant signals: sales speed, supplier delays, sudden demand changes, outside trends, even weather and events. They adjust all the time, not just every static report cycle (which could be months).

High-performing teams use:

-

Predictive models that improve with every cycle.

-

Adjustments based on context that change for promotions, unusual events, and happenings.

-

Feedback loops that measure accuracy and tune parameters automatically.

Real-Time Visibility Through Smart Sensors and Systems

You can’t optimize what you can’t see. Most businesses are still seeing their inventory in delay, long after problems crop up.

In contrast, a smart inventory system brings instant clarity:

-

Connected systems and sensor integrations provide up-to-date visibility from shelves, warehouses, and delivery routes.

-

Connected systems like resource planning, warehouse management, and sales points sync all the time, not in groups.

-

Dynamic dashboards show where products are, not where they were.

Automated Decision-Making Where It Matters Most

Artificial intelligence doesn't replace people. Instead, it helps them by handling simple tasks and providing insight into more complex topics.

An effective stack supports automation by tapping into:

-

Restocking rules. Automatically generate recommended orders based on current demand.

-

Threshold triggers. Initiate alerts or actions when certain conditions are met.

-

Handling exceptions. Send unusual cases to people, not the entire process.

Importantly, artificial intelligence automation isn't all or nothing. The best setups involve AI systems suggesting actions while people oversee those suggestions and implement them. This builds trust without losing control. This allows your operation to move with confidence by leveraging data you can actually act on.

Four Proven AI Inventory Management Plays You Can Run Right Now

Here are four quick, targeted actions that create immediate value using artificial intelligence in real work settings. Each example is time-boxed, scoped, and tied to a measurable outcome.

AI Forecast Tune-Up

Goal: Improve demand prediction accuracy in 5 days.

When to use it: Planning next quarter's forecast or fixing ongoing performance fluctuations in specific products.

Steps to execute the play:

- Identify 5 to 10 products with inconsistent or unpredictable demand

- Pull 12–18 months of historical sales data (plus any seasonal or promo overlays)

- Run a predictive model (start with open-source or vendor-provided tools)

- Compare against the current forecast accuracy

- Adjust parameters and retrain based on variance

Win condition: ≥15% reduction in forecast error for pilot products.

Sensor Pilot Sprint

Goal: Establish real-time visibility in 7 days.

When to use it: Warehouses or zones with frequent inventory mismatches or miscounts.

Steps to execute this play:

- Select a single storage area, zone, or group of products

- Install cheap sensors (radio frequency identification, weight, camera vision)

- Connect to a live display or feed (for example, through warehouse management or an outside tool)

- Monitor for 7 days and respond to alerts manually

- Log alert-response time and accuracy

Win condition: Zero stockouts or physical count errors during pilot.

Anomaly Alert Audit

Goal: Turn inventory differences into ongoing improvement. Find causes and add fixes to processes.

When to use it: Use this approach when teams face alert overload or can't trace inventory discrepancies.

Steps to execute this play:

- Get system alerts and marked unusual events from the past 30 days for review

- Group by pricing, sales speed, stock shortages, and delivery mismatches

- Cross-check manual logs or sensor data for validation

- Implement rule refinement or data hygiene fix

- Add rules for sending future unusual events to the right people

Win condition: ≥50% reduction in repeat unusual events within 2 weeks.

Auto-Replenishment Deployment

Goal: Automate simple ordering decisions for fast-selling products.

When to use it: Use this to stop repetitive order tasks for teams wasting time on manual ordering.

Steps to execute this play:

- Identify products with steady sales speed and reliable supplier delivery times

- Set minimum stock thresholds and reorder quantities

- Set up automatic triggers through resource planning, order management, or an outside connection

- Route approvals to the buyer for exception handling only

- Monitor delivery accuracy and on-time performance

Win condition: 80% of orders are automatically generated and reviewed without manual entry in the test category.

Each of these starting points builds institutional knowledge, smooths out your processes, and frees up operational bandwidth for strategic thinking.

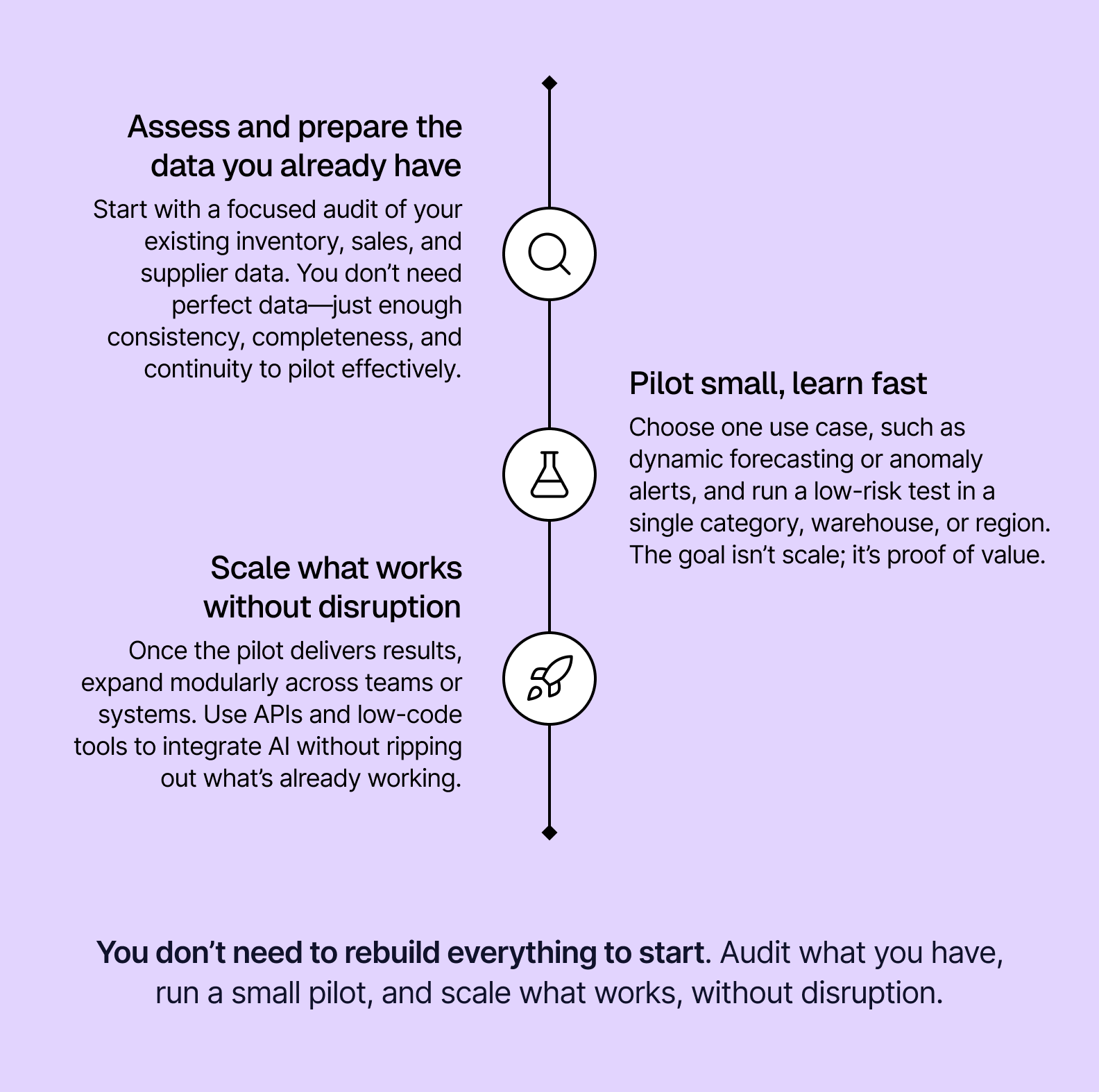

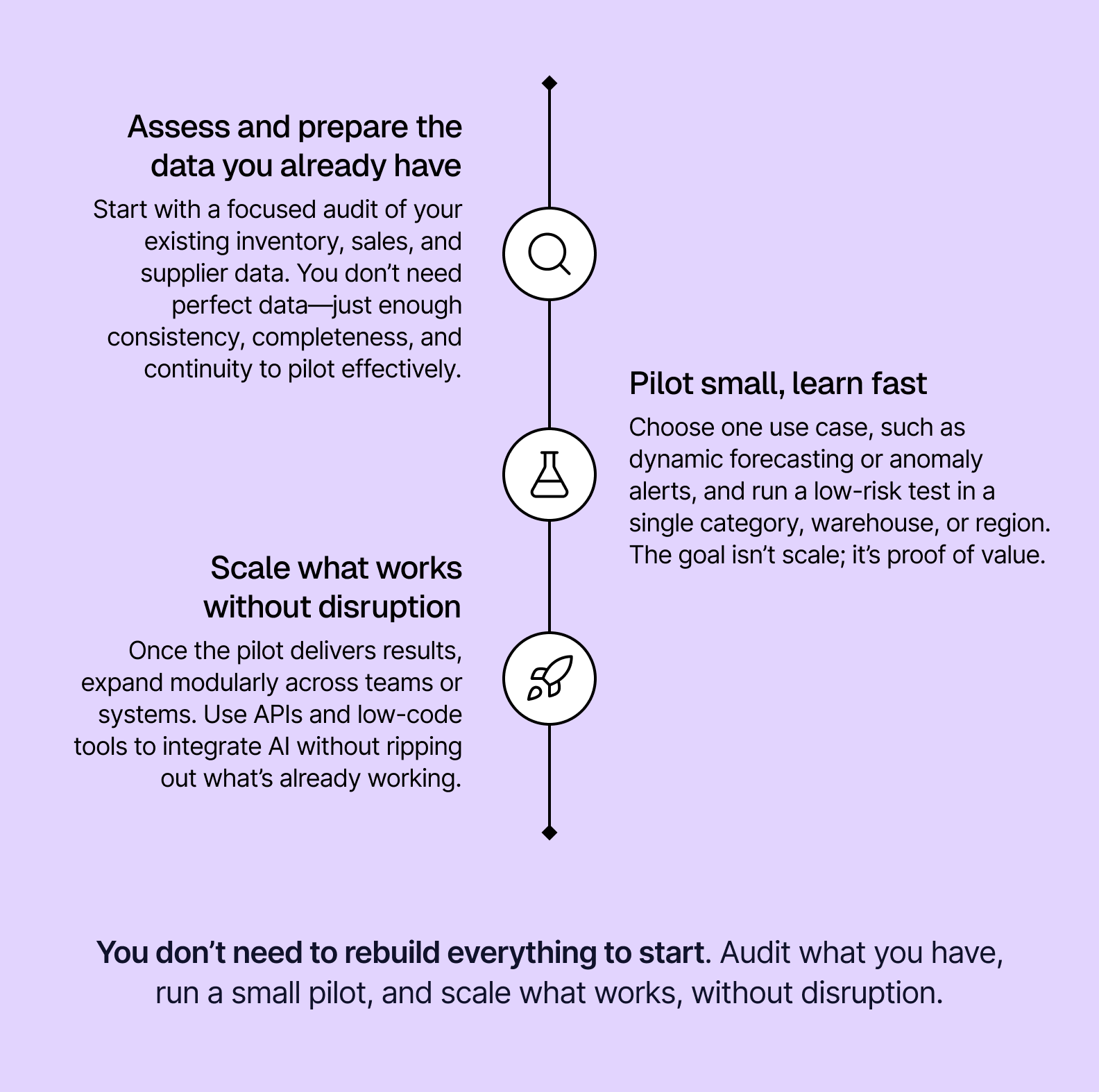

Your Next Move

You don’t need a complete overhaul. Just the first few wins, powered by tools like Tailor.

Building on the effective plays above, this isn't about becoming smart-system powered overnight. It's about building the first few wins — small, real, and useful for operations.

Tailor is purpose-built to turn these plays into reality:

-

Flexible, independent design lets you add smart logic to your current processes like detecting unusual events or triggering restock recommendations. Tailor can integrate seamlessly so you don’t have to rip out your current system.

-

Simple setup pipelines and event starters make it easy to create workflows with people involved. Our system flags unusual events and your team approves, turning insights into actions.

-

Mid-market to enterprise readiness. Brands already using Tailor are running complex processes at scale. They’re able to pilot a smart replenishment or visibility sprint without disrupting their operations.

Tailor's composable, API-first ERP gives you control, visibility, and flexibility in smart inventory management — letting you run these actions quickly, with minimal setup and without heavy technical overhead.

Ready to see how Tailor can help you run these plays — without the implementation headaches? Schedule a demo